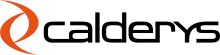

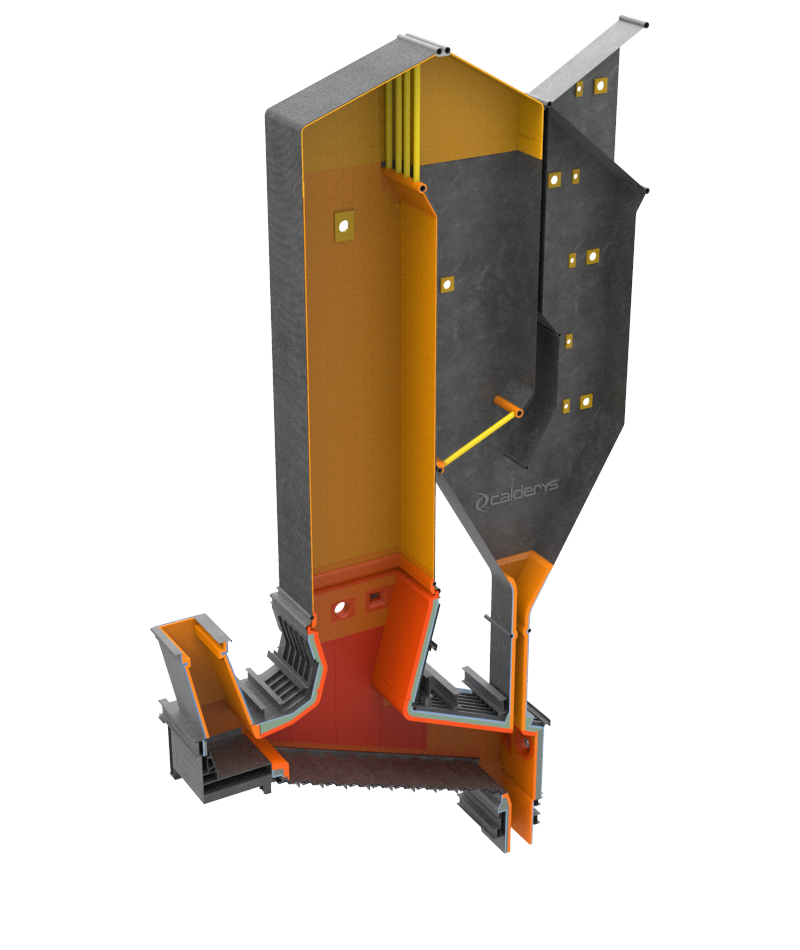

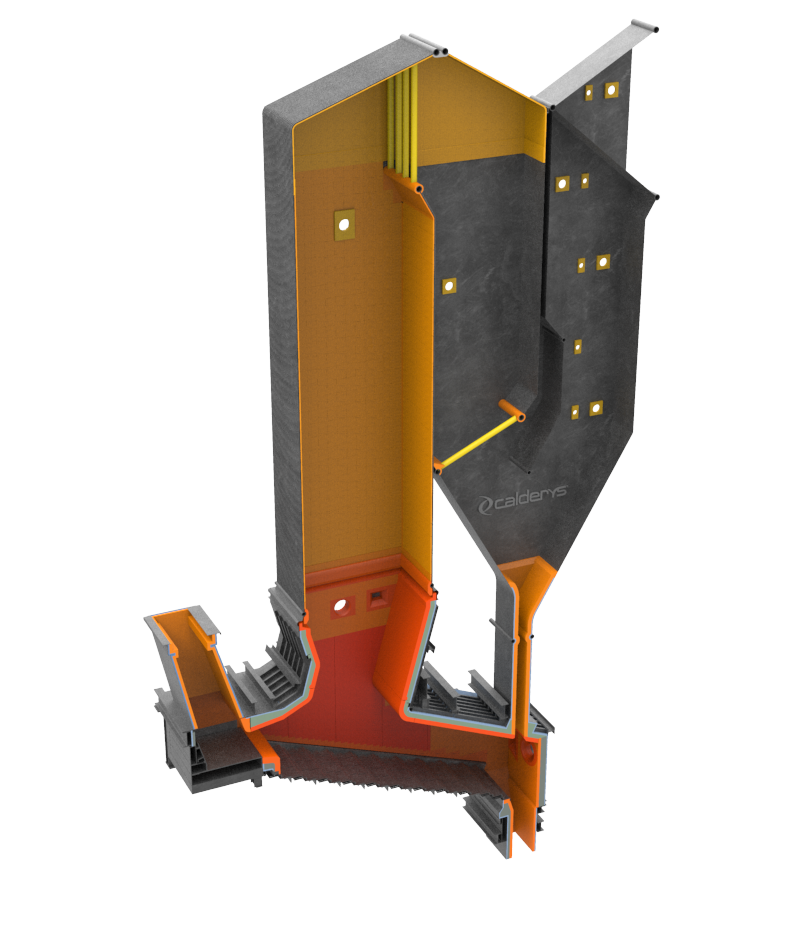

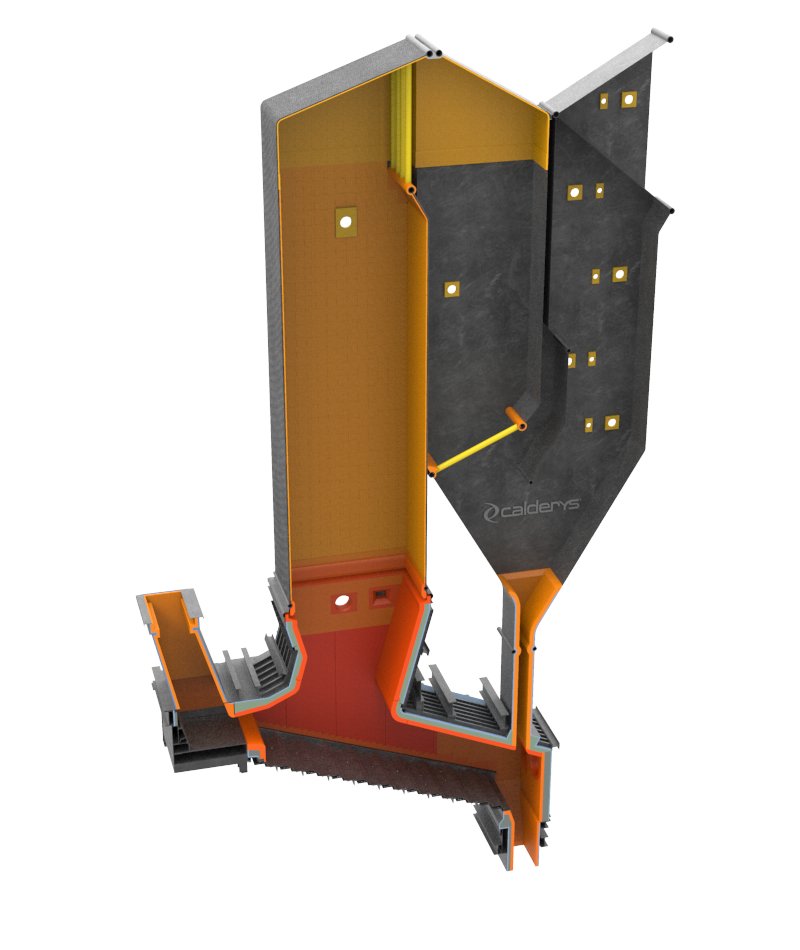

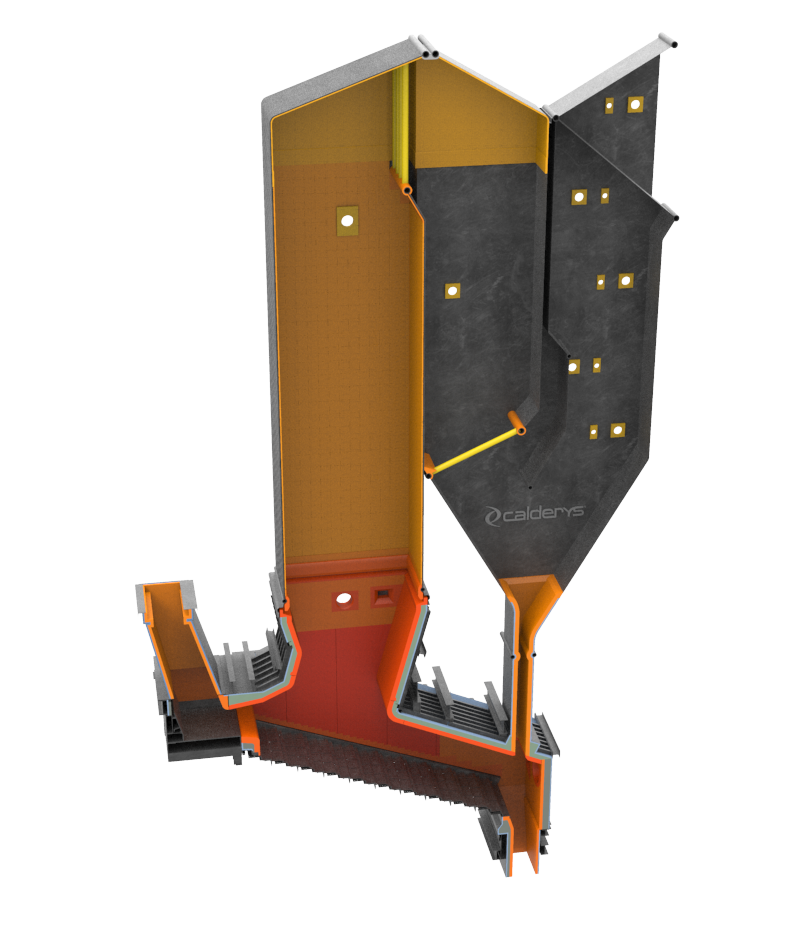

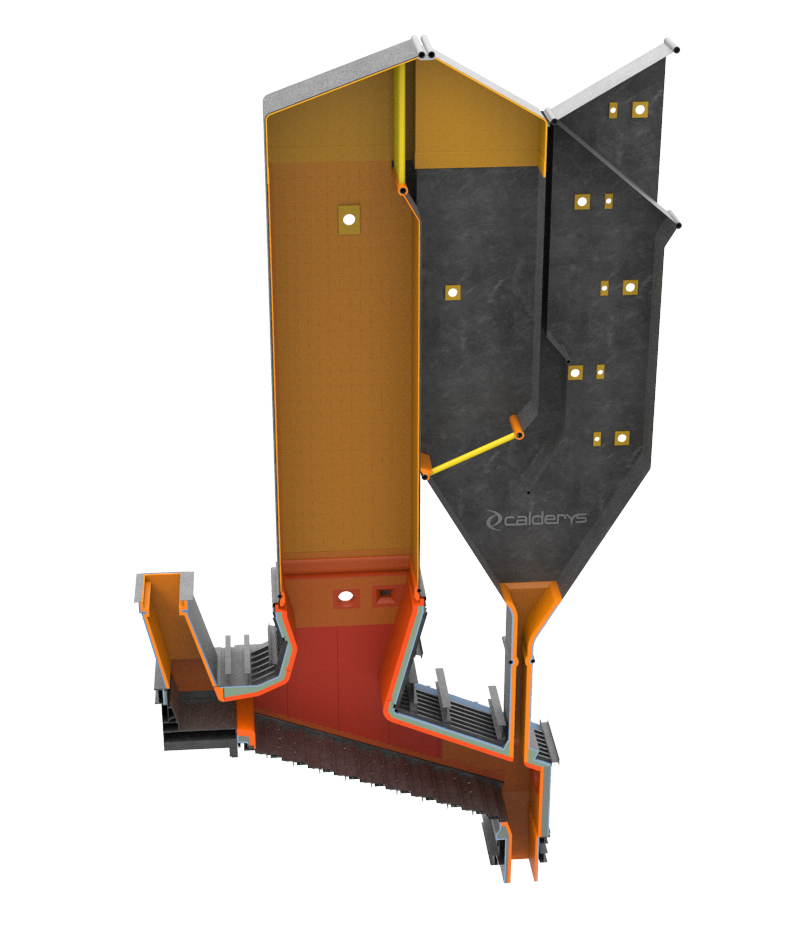

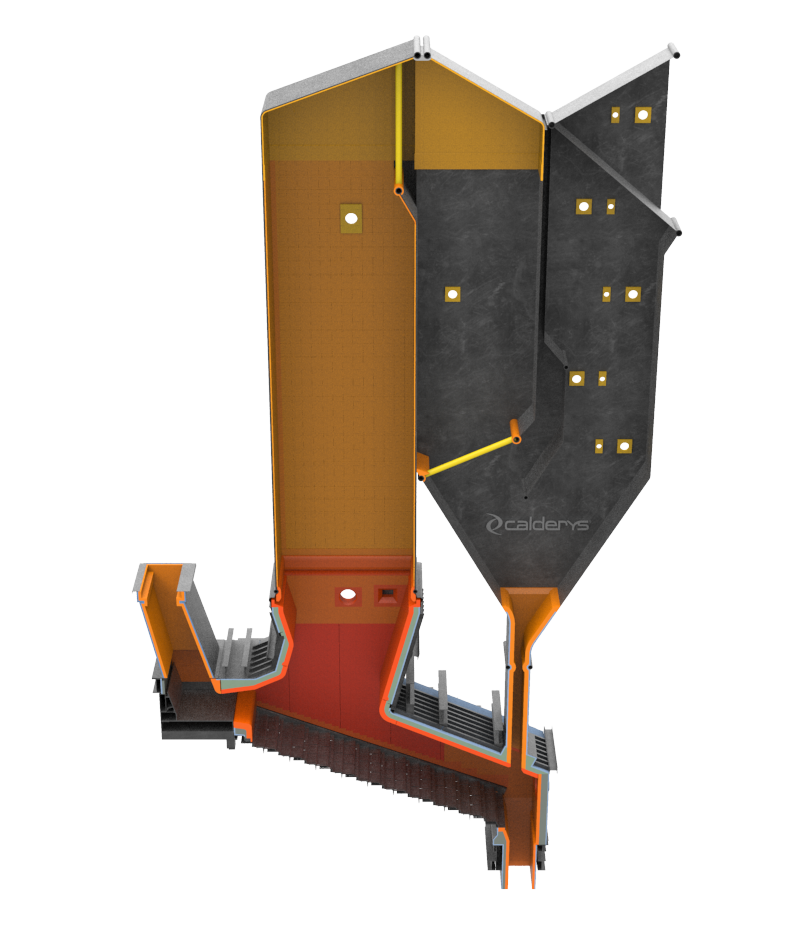

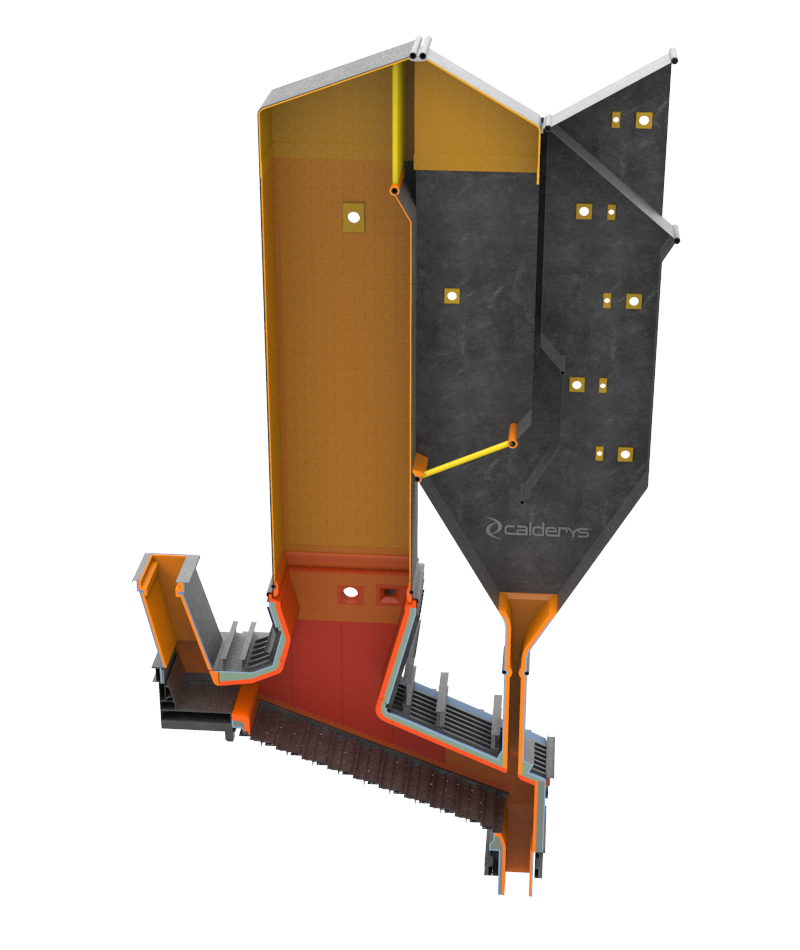

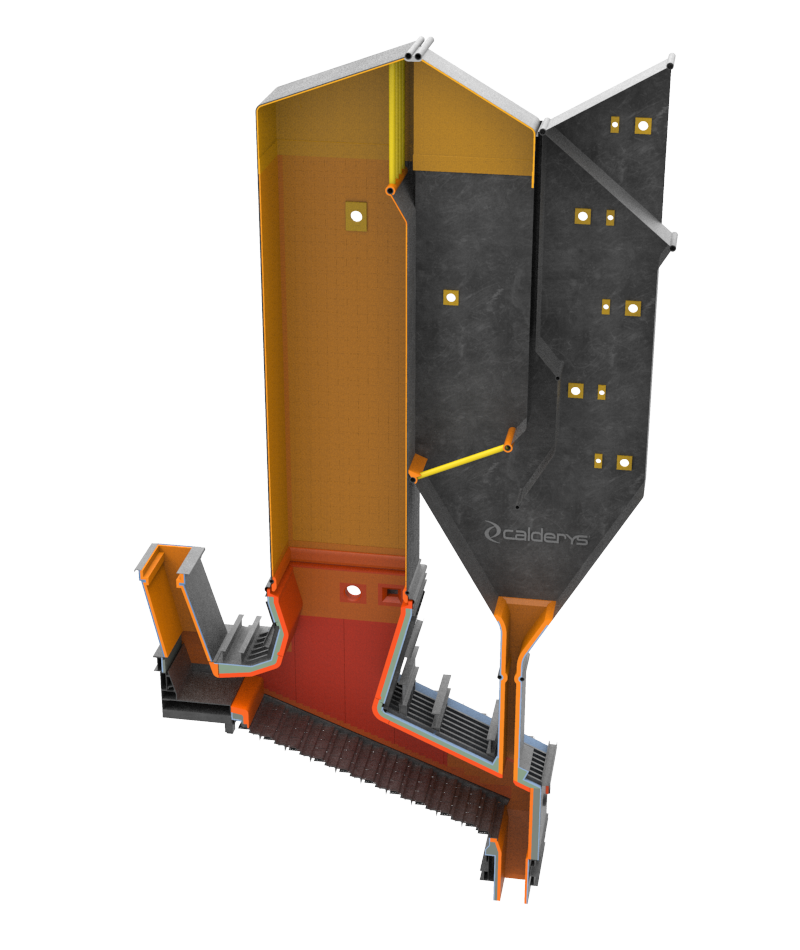

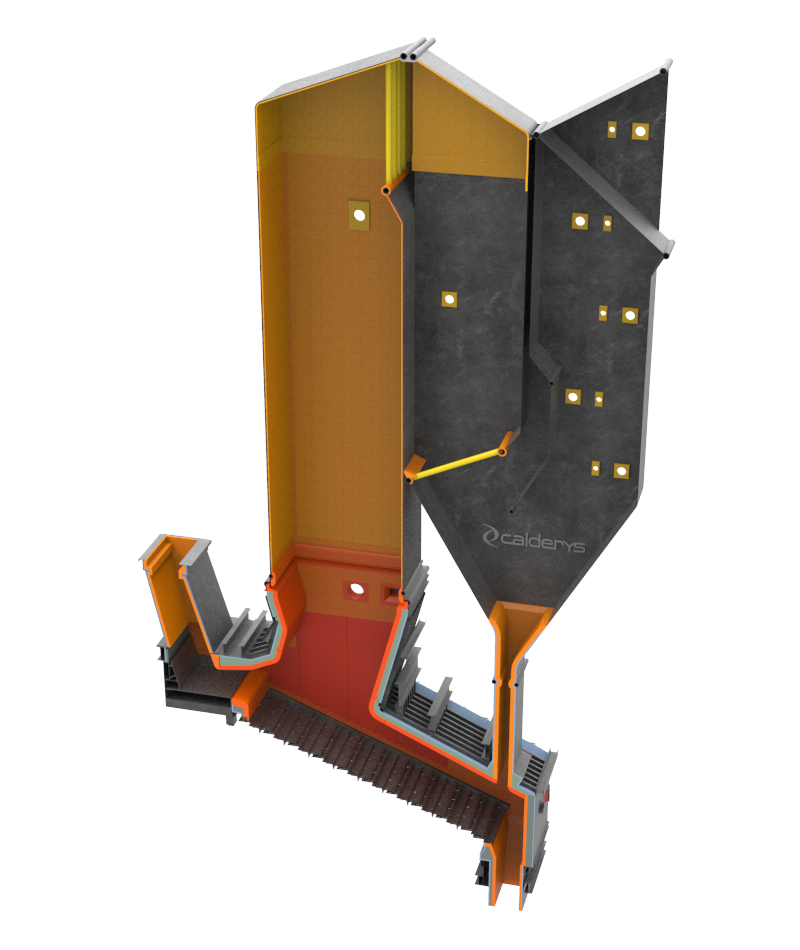

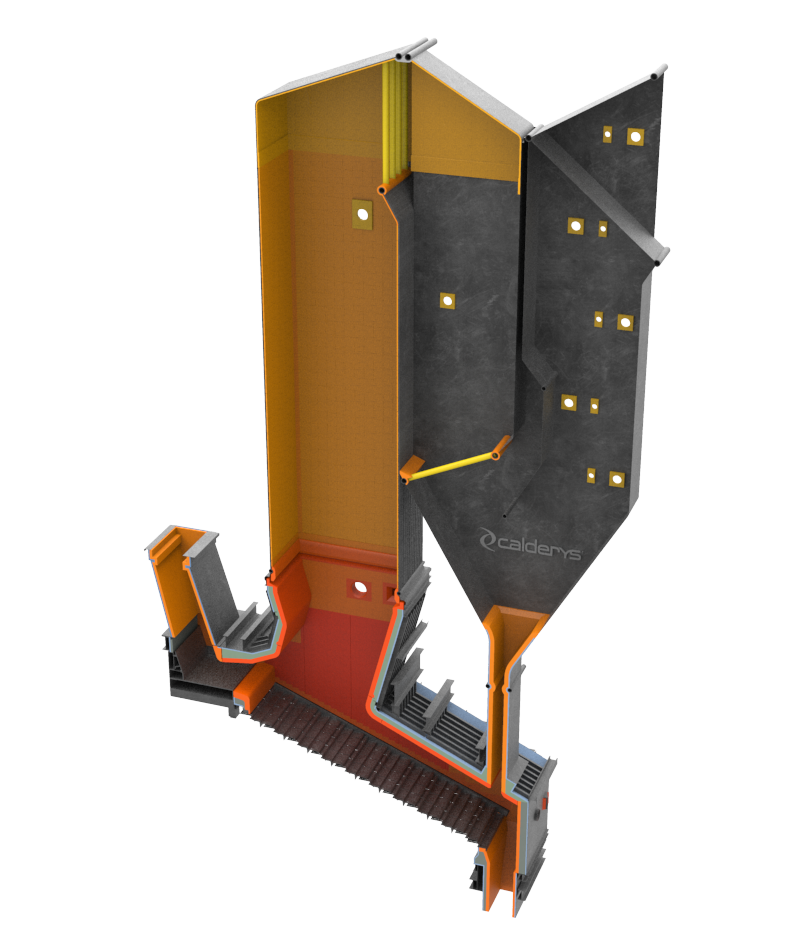

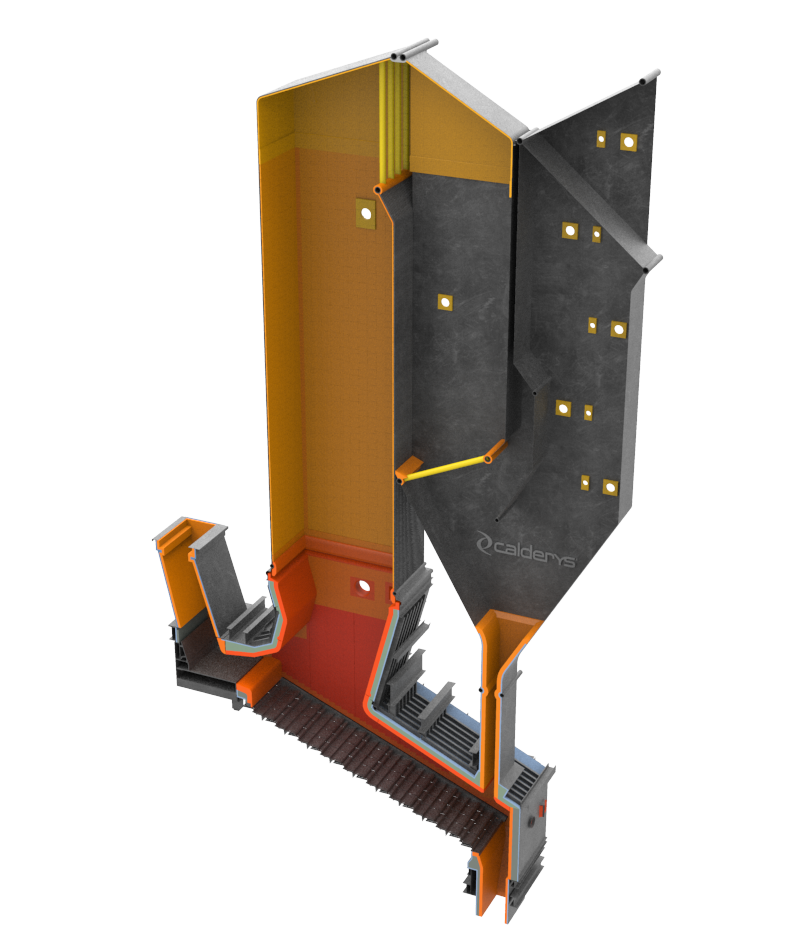

Grate-Fired Boiler

This boiler and incinerator technology, one of the standards globally for waste-to-energy over the years, is well-known for high abrasion due to waste impacts along the grate. The mix of waste feedstock during operation is also an important consideration for your refractory lining, where the experts at Calderys will work closely with you for the ideal solution: from high-quality products (using shaped or unshaped refractory) all the way to a full turnkey project.

This boiler and incinerator technology, one of the standards globally for waste-to-energy over the years, is well-known for high abrasion due to waste impacts along the grate. The mix of waste feedstock during operation is also an important consideration for your refractory lining, where the experts at Calderys will work closely with you for the ideal solution: from high-quality products (using shaped or unshaped refractory) all the way to a full turnkey project.