Partner to top ironmakers

Calderys has gained decades of experience providing specialized solutions from the blast furnace to the casthouse floor. The key benefits of Calderys refractories for ironmaking include:

- Boosted productivity: longer service life for your equipment and reduced maintenance downtime.

- Greater cost-effectiveness: optimized solutions to suit operating conditions and reduce hot metal unit cost.

- Always a step ahead of CSR changes, based on safety, reliability and high performance refractory solutions and products.

OUR SERVICES

REFRACTORY SERVICES

Calderys offers a full range of services, tied in closely with our world-leading high temperature solutions product lines. We are continually upgrading our services and equipment to ensure that our products are easy and safe to use.

Material selection

Our expert engineers with a deep understanding of your local market, industrial process, and the chemical reactions in your equipment will work with you to identify the best products in terms of performance, lifetime, and cost.

PROJECT MANAGEMENT

Our end-to-end project management services offer you the peace-of-mind you need to focus on your production.

TECHNICAL SUPPORT

Calderys offers full technical support, thanks to a global network of technical experts, acting locally wherever you need it.

Your Equipments

Blast Furnace

Repairing the stack allows to extend the lifetime of the blast furnace and to insure best possible productivity and constant quality of the cast iron at the lowest possible consumption of coke and energy.

All Details

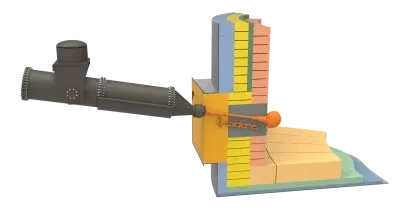

Tap-Hole

Tap-hole clay manufacturer for over 40 years, Calderys will put its experience and expertise to work for you with customized tap-hole clay options, to optimize the 3 main operations of a blast-furnace: plugging, opening and casting operations.

All Details

Casthouse Floor

Our castables for iron troughs are designed to combine a total reliability with a reduced maintenance downtime, whatever the length of the campaign.

All Details