Steel Ladle

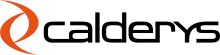

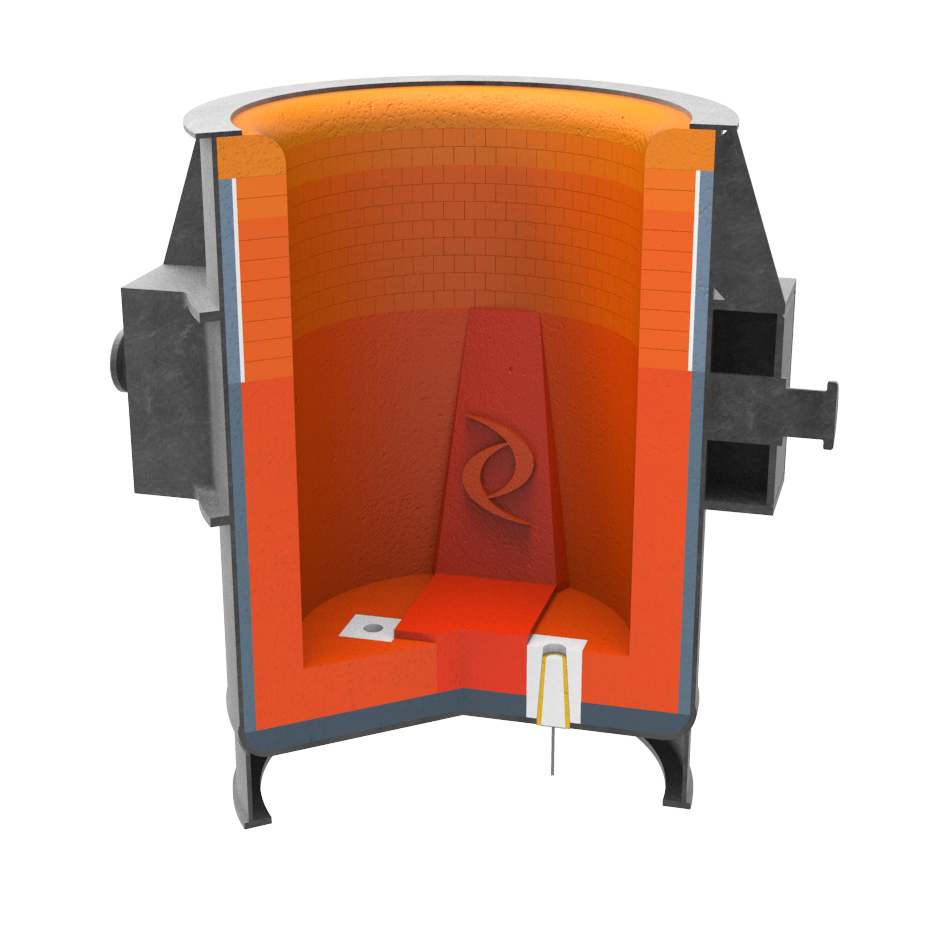

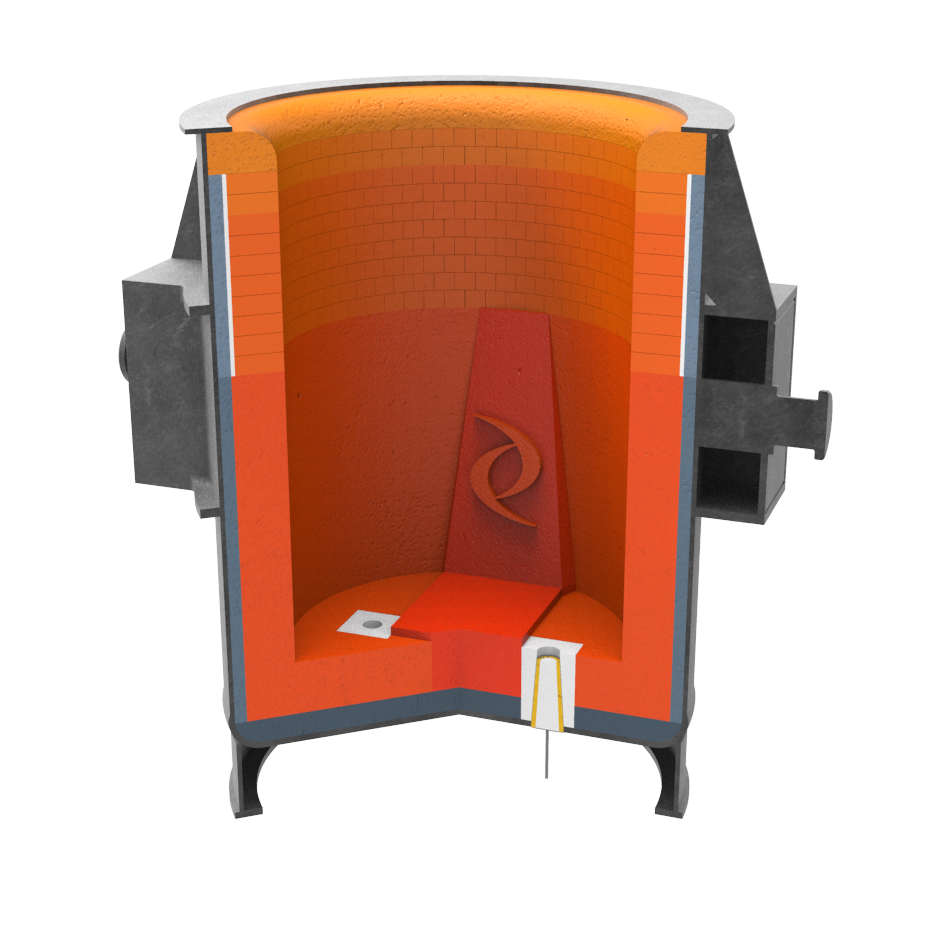

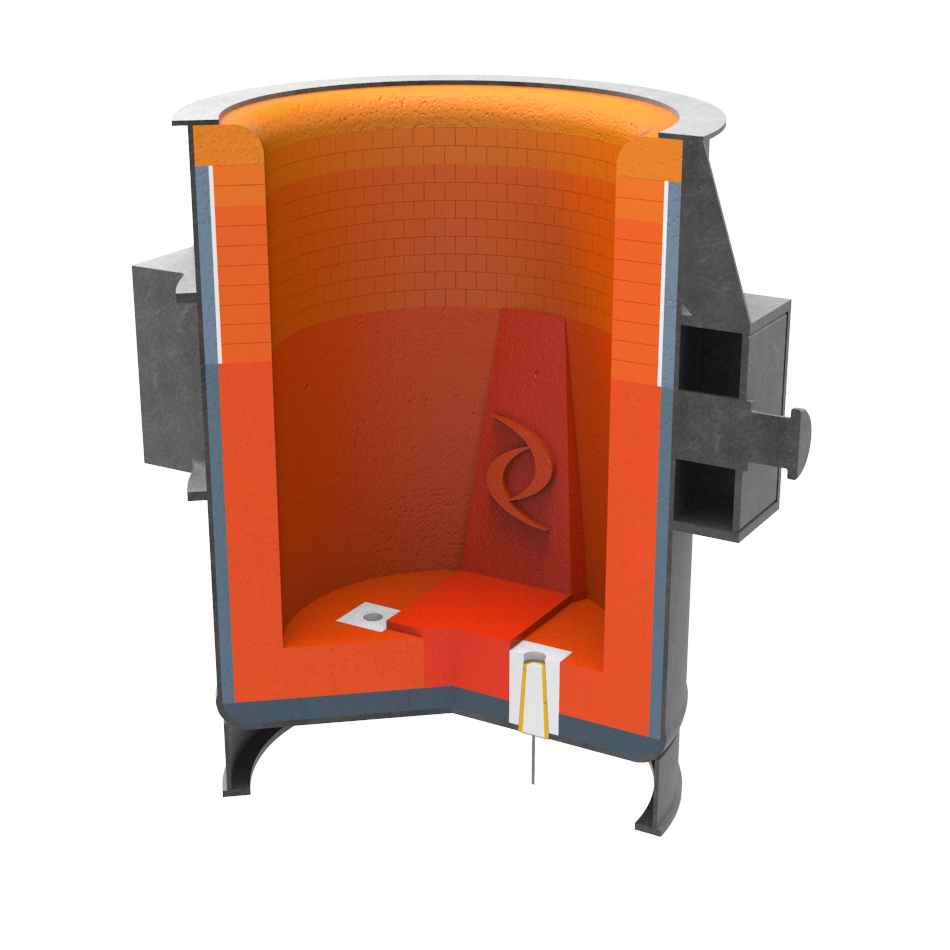

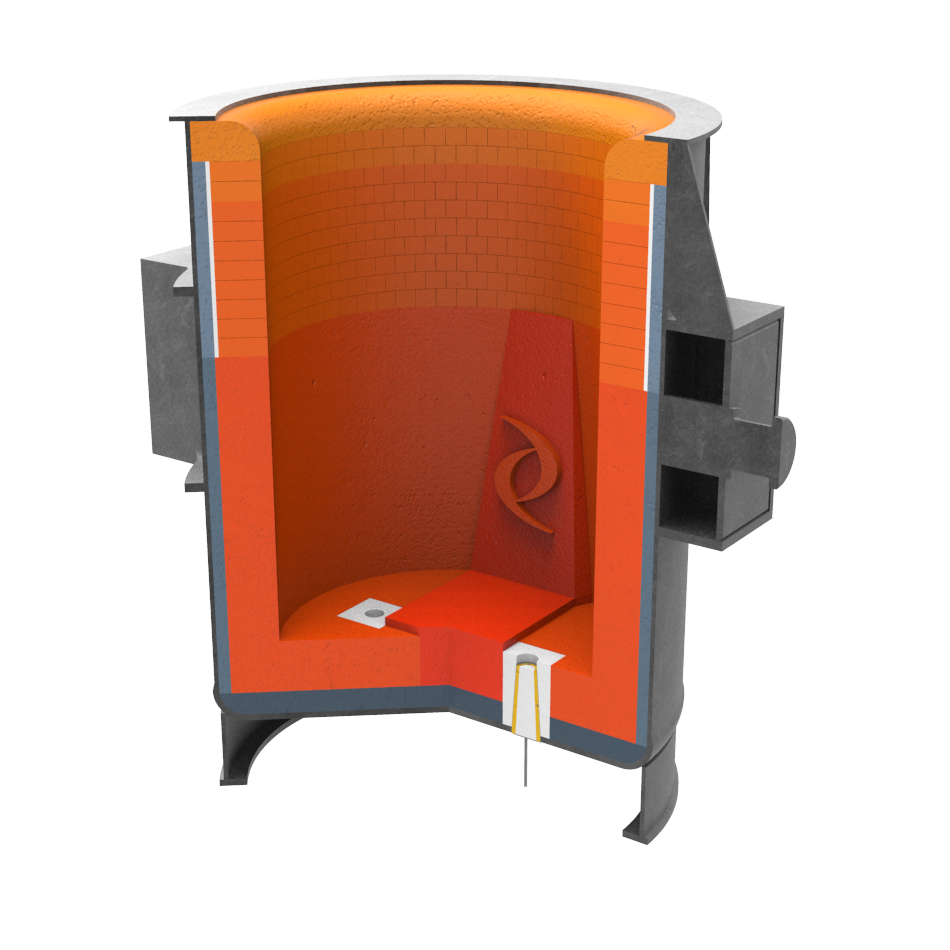

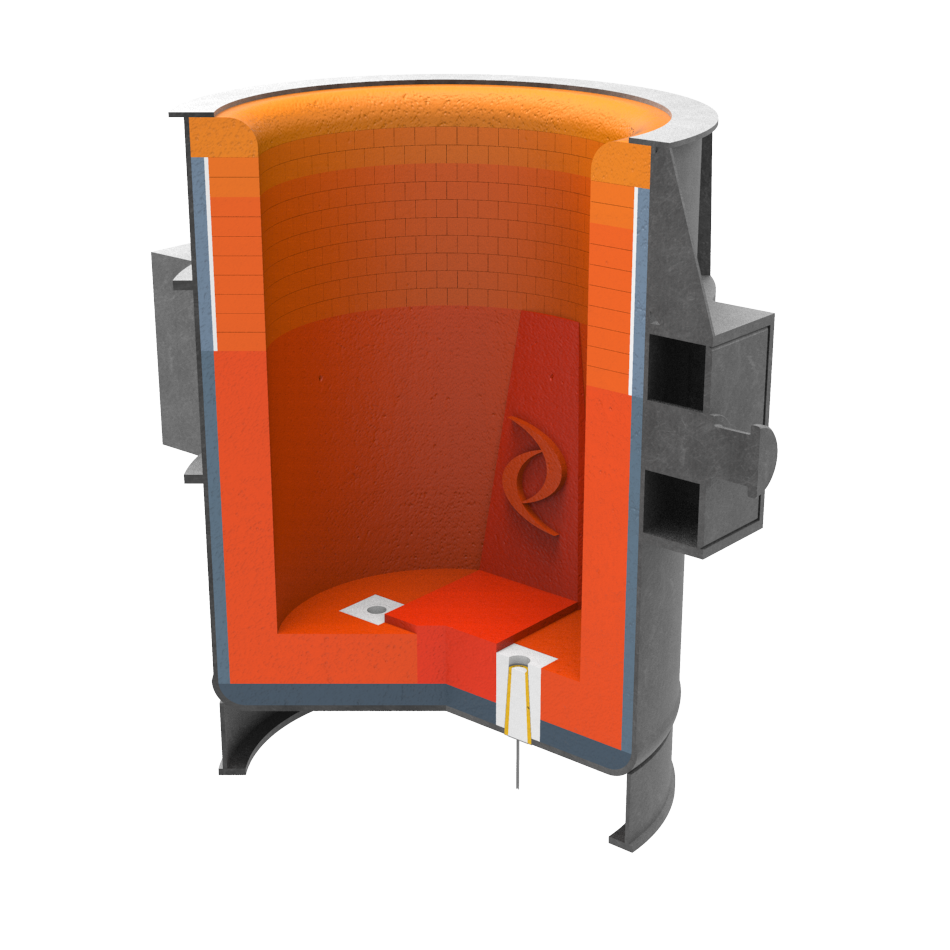

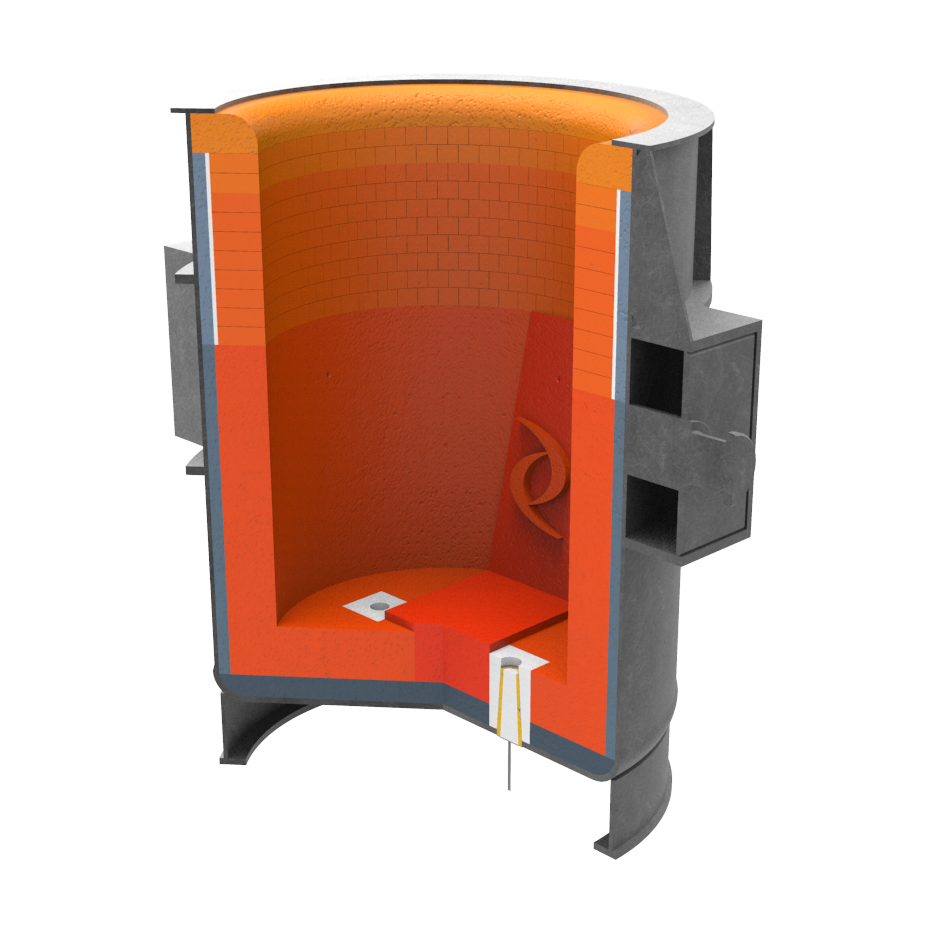

Our multi layer product designs are created to provide best possible thermal insulation to conserve energy, and to reduce the deformation effects on the steel shell structure.

STEEL LADLES LINING

From its global operational footprint, Within the dynamic world of ladles, secondary steelmaking continues to become more demanding, with long resistance times and higher processing complexity, as the push for cleaner and greener steels become more important. Our multi layer product designs are created to provide best possible thermal insulation to conserve energy, and to reduce the deformation effects on the steel shell structure. As well as initial refractory linings, Calderys offers the full range of dedicated repair products and services, to further extend vessel life.

Beyond refractories, as part of its corporate responsibility, Calderys has the means to evaluate the complete technical, commercial and environmental scope of refractory usage, from CO2 emissions, yield management, circular economy, waste management, energy consumption and environmental footprint.

The Calderys range of puring systems for liquid steel, whether lances or purging plug assemblies, are designed and constructed to the highest possible specifications.

Our range of argon lances are produced from the highest quality castable technology, providing high levels of erosion and corrosion resistance. Our lance steel construction has been digitally designed to offer the best possible strength and rigidity, to reduce the risk of flexural and bending stresses.

TAILOR-MADE LANCES

Customized lances with 3 different zoning (upper bath, slag line and metal bath) to support any type of treatments in the steel ladles

- for steel bubbling

- for steel treatment: equipped with V-anchors, to avoid risk of vertical cracking

PURGING PLUGS

The Calderys portfolio has been developed to optimize the 3 main performance indicators :

- Lifetime / Stirring time

- gas flow rate

- opening rate

We propose various solutions depending on the process:

High gas flow rate - hard stirring:

- Slot (Standard plug): CALDE™CAST LT 90 SP G8 and CALDE™CAST LT 96 SP. The flow rate can be adjusted by different number of slots.

- HP (Ring channel): Recommended plug for hard stirring: we recommend the same composition than above. The flow rate can be calculated and the opening rate is better than the regular slot.

Polyvalent

- HP2 (patented by Calderys): combination of ring channel & porous center, adjusted flow rate and better opening rate than porous option.

Soft steering

- Porous (specific composition): a controlled grain size for smaller bubbles & higher specific surface, adjusted for low flow rate. This option offers less infiltration of slag in the plug.

METALLURGICAL FLUXES

- LDSF RG : original recipe for slag conditioning & desulfurization

- Optimet : to improve the refractory lifetime of the slag lining

- LDSF LT & ULT : for high purity steel grade with Titanium constraints.

- LDSF HT : To improve Titanium yield for

- Ti-stabilized stainless & improve recyclability of the slag