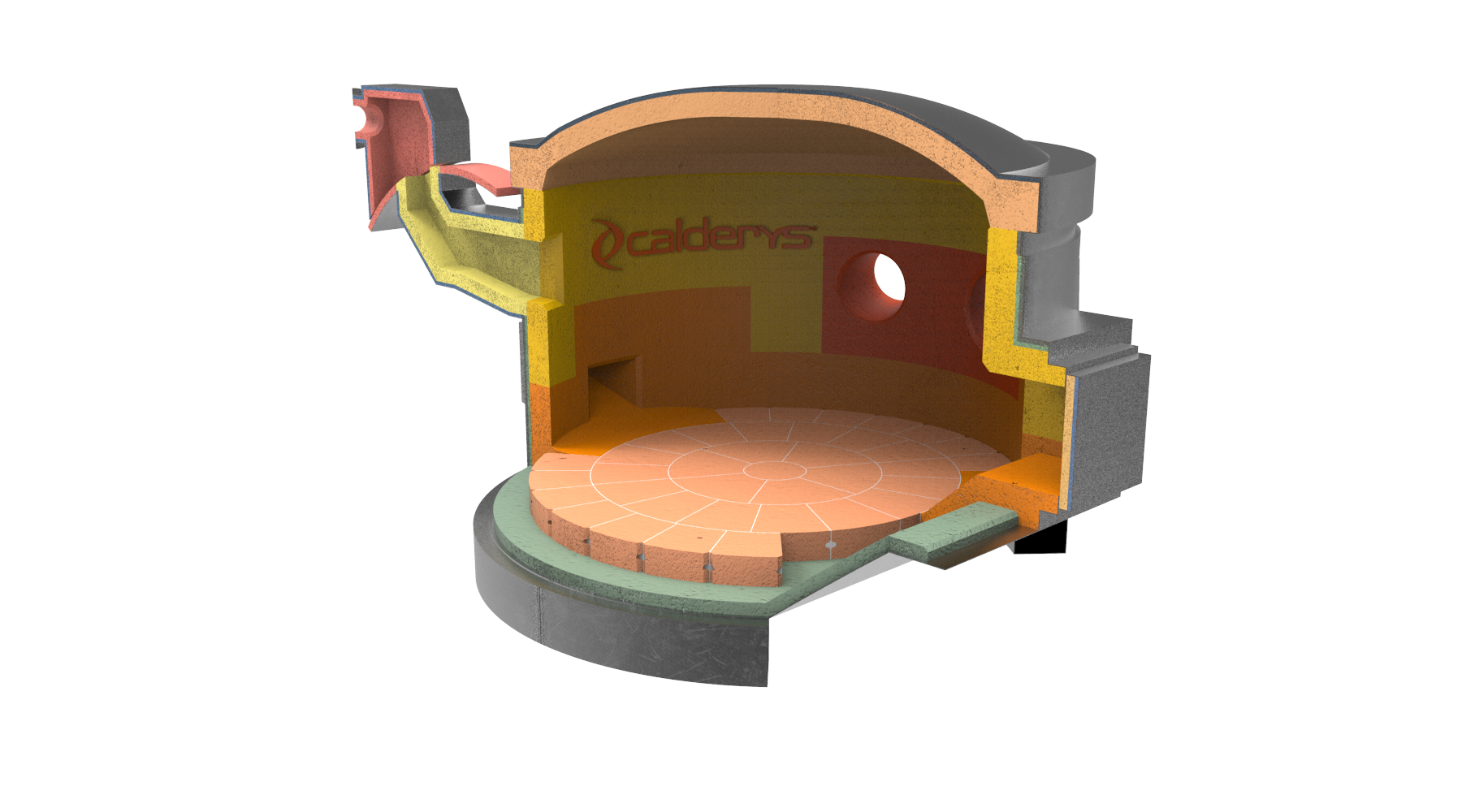

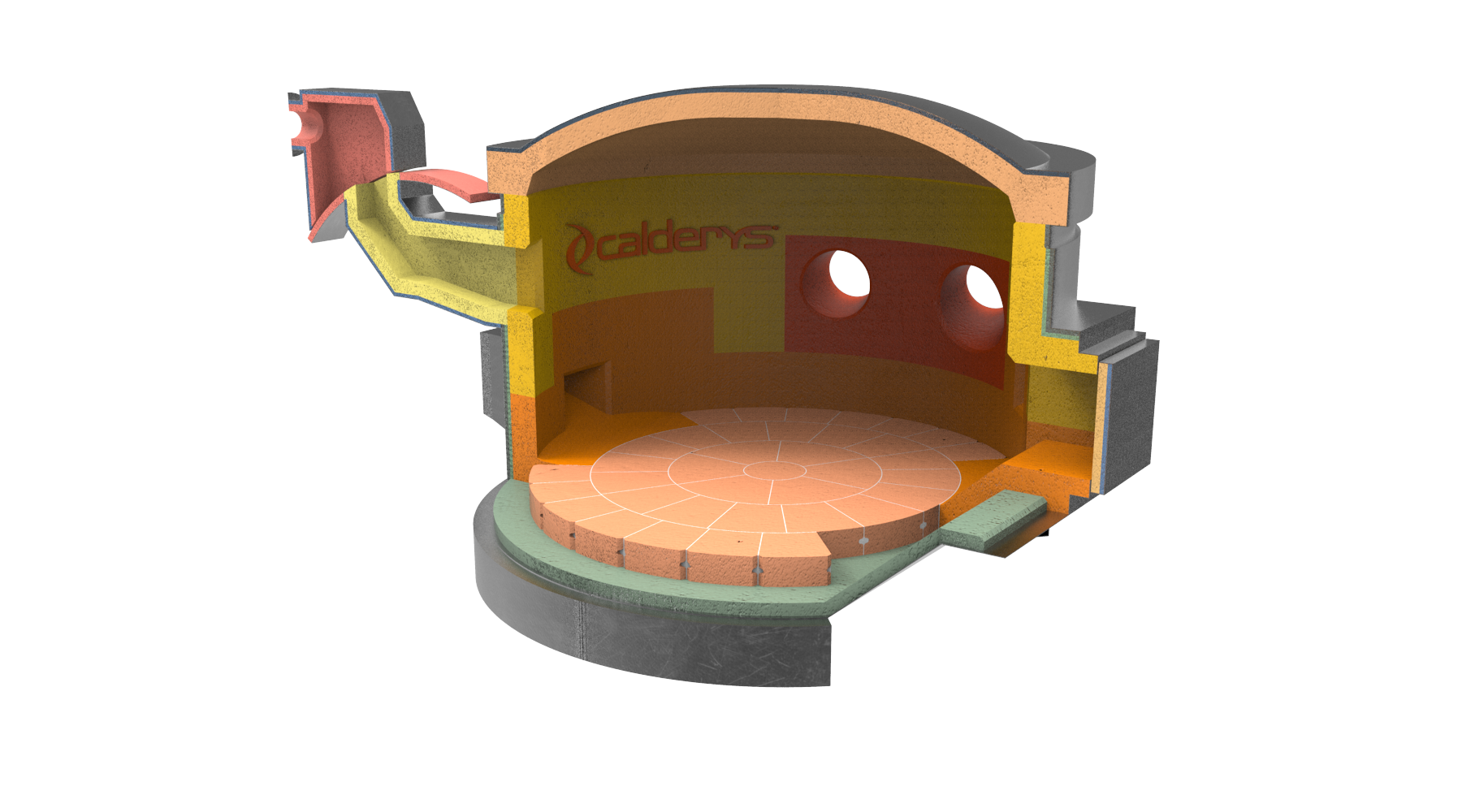

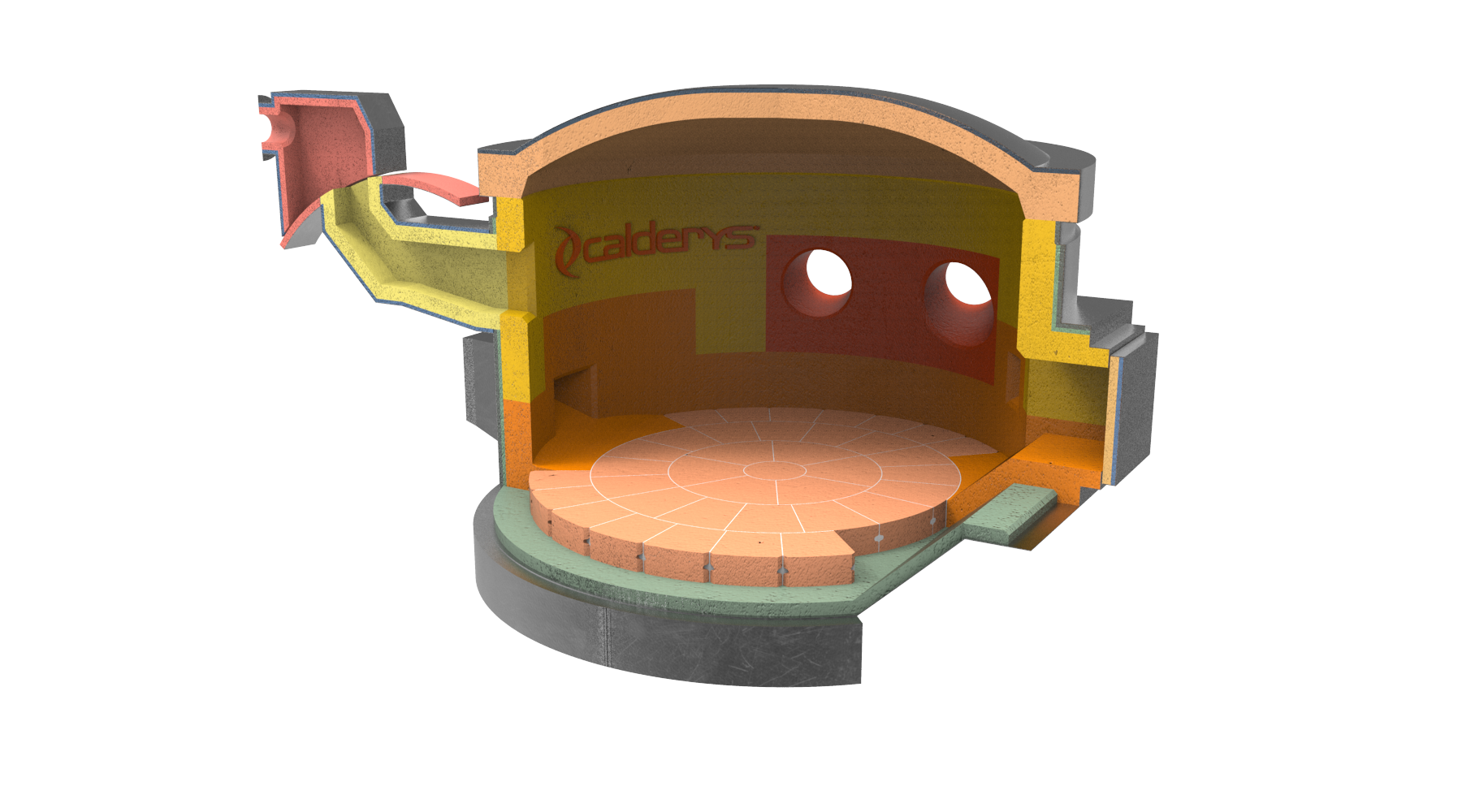

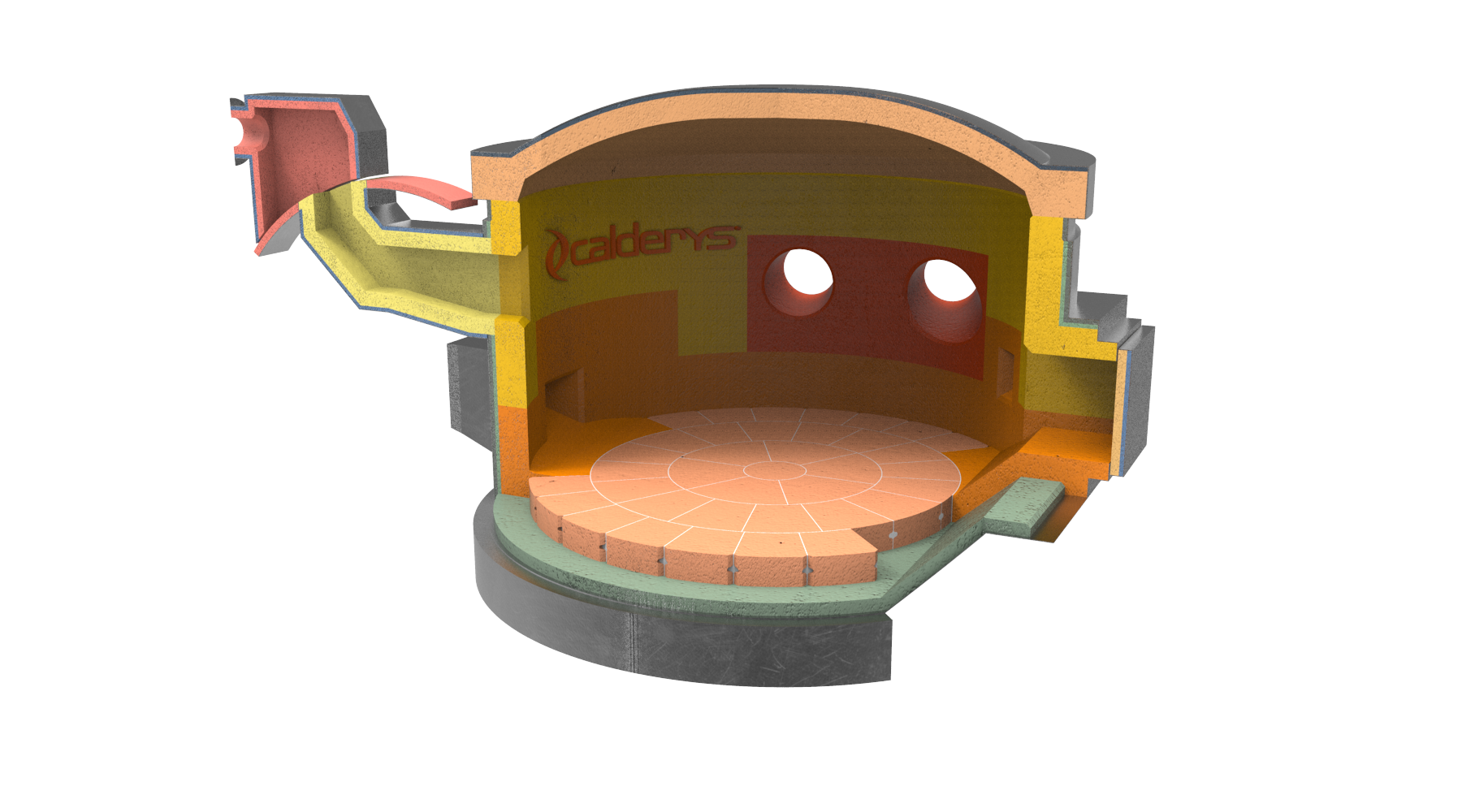

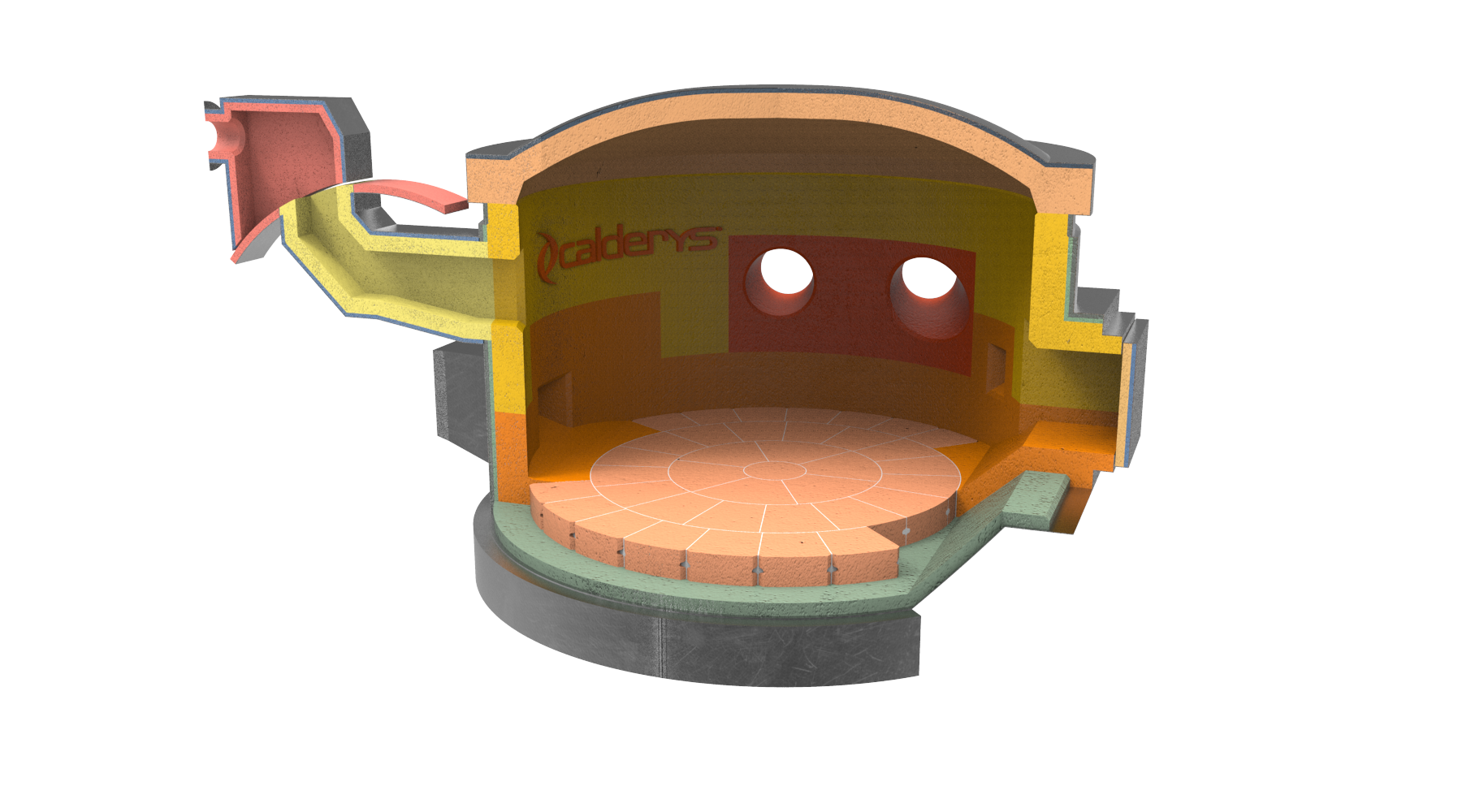

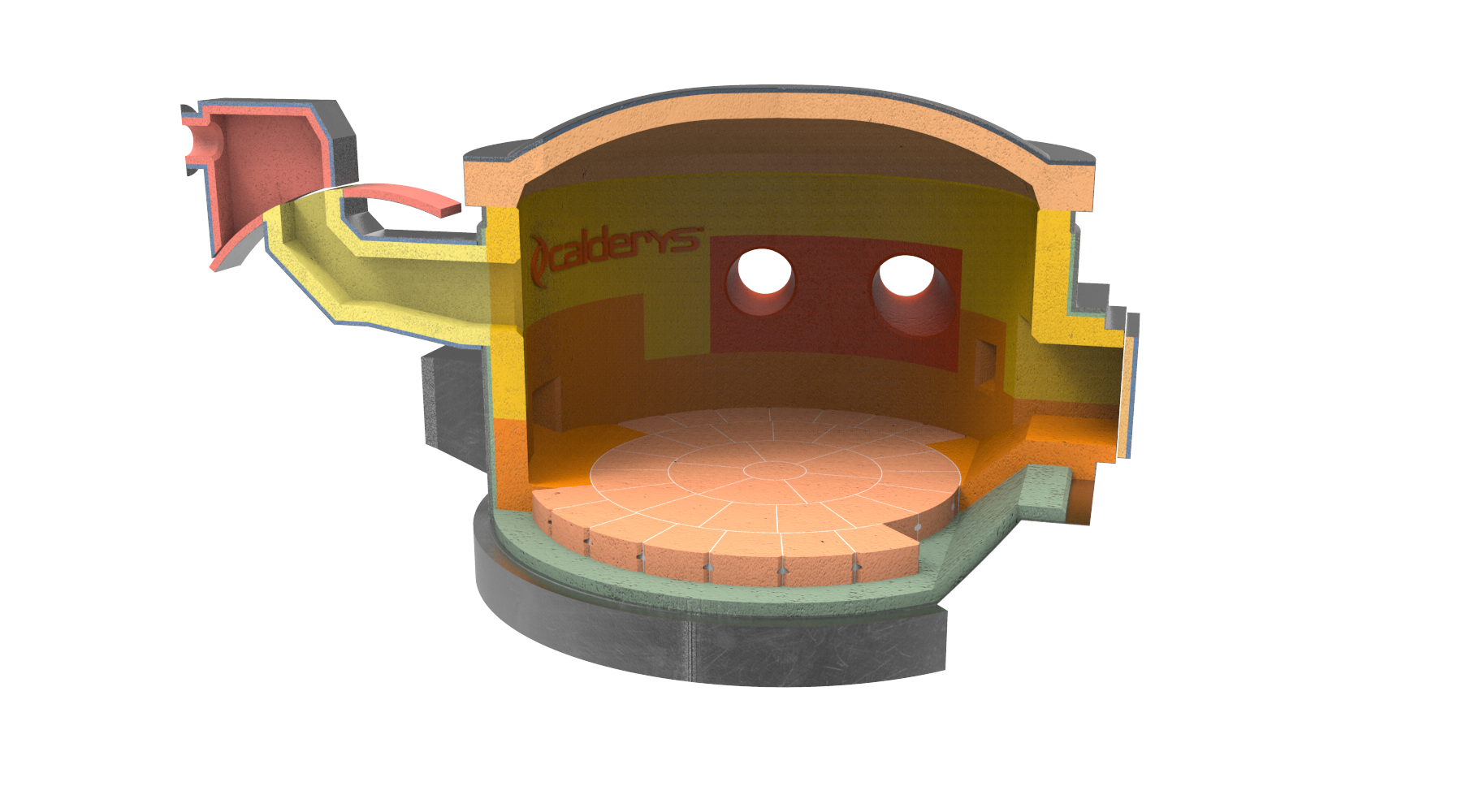

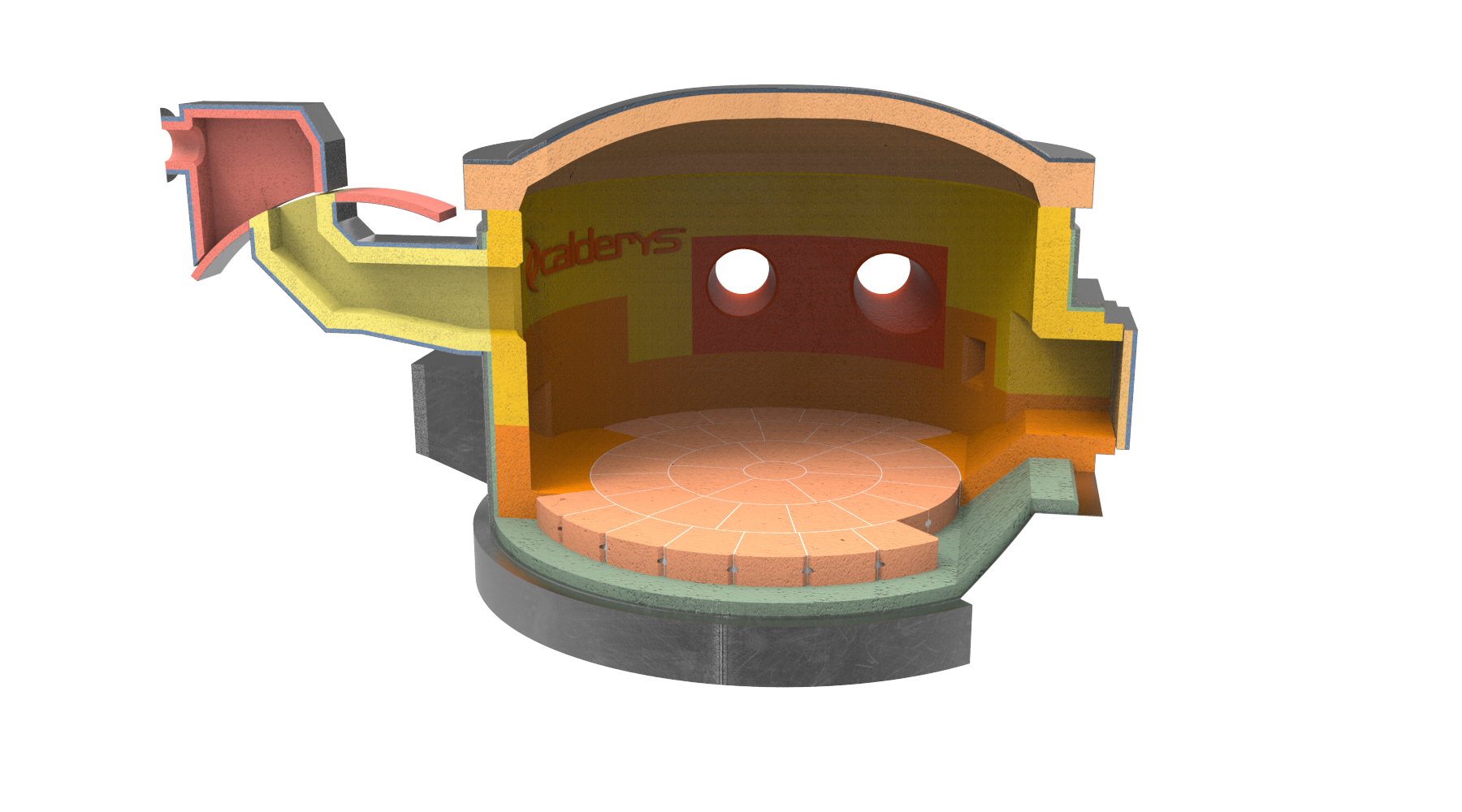

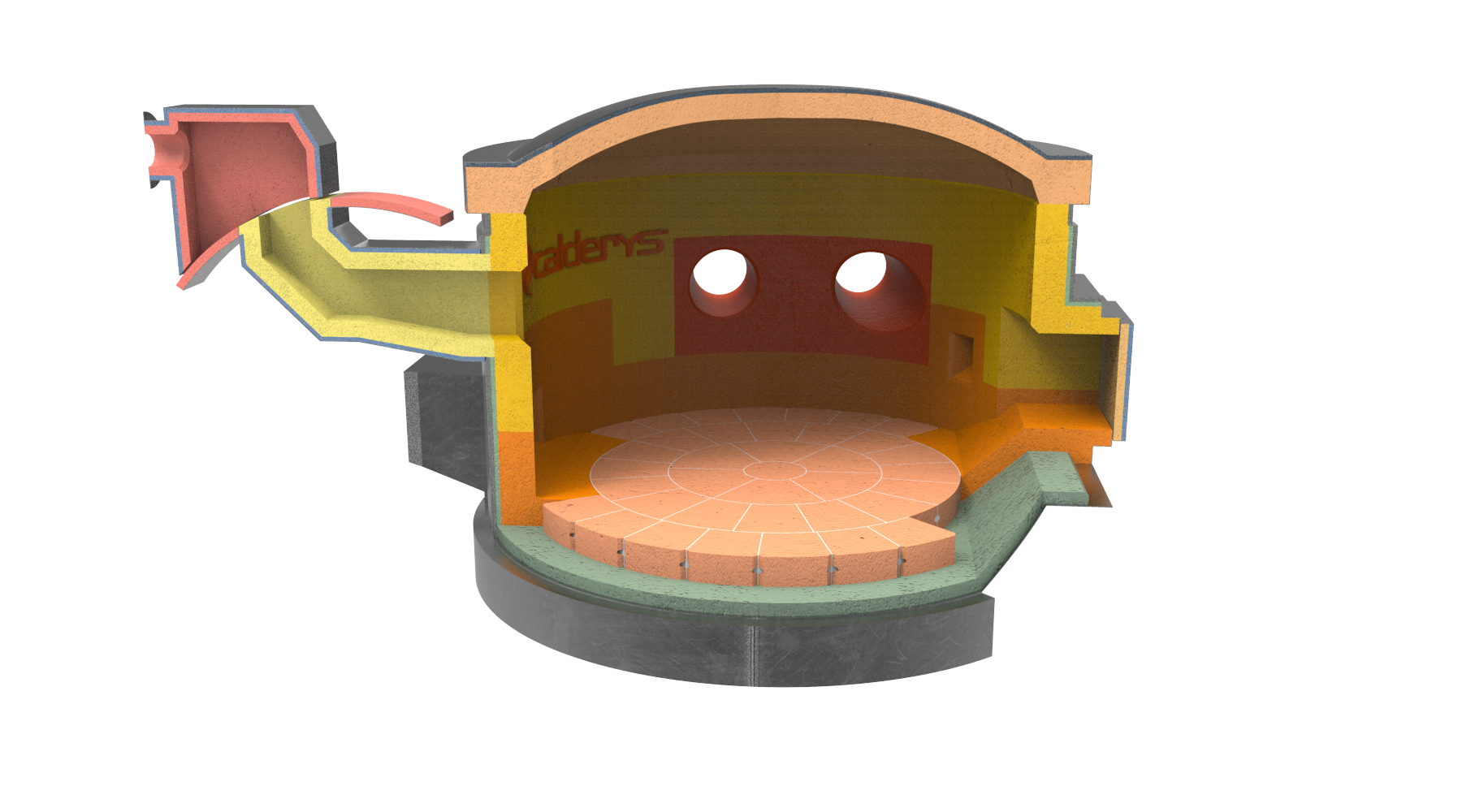

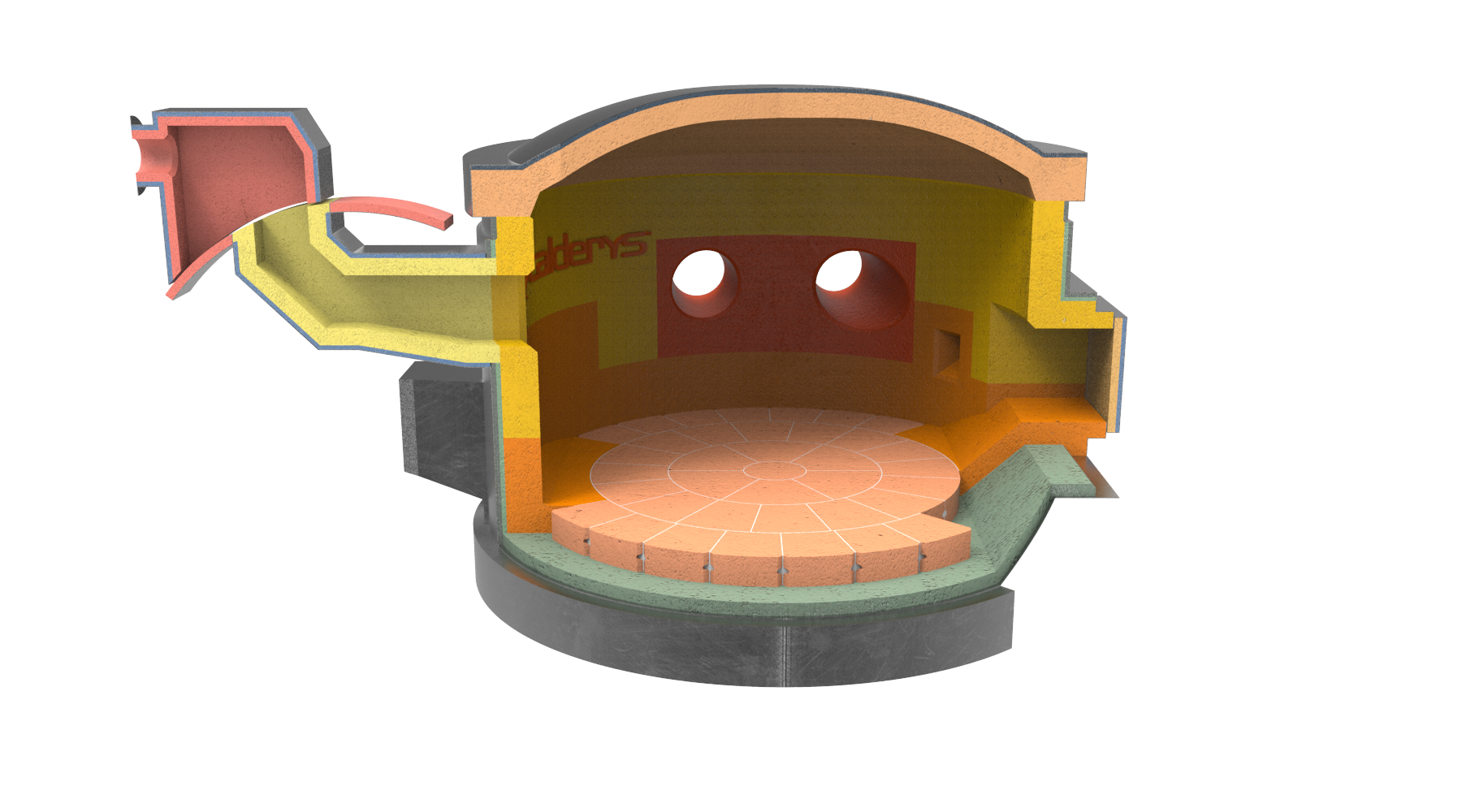

Top Charging Furnace

From monolithics to refractory expertise, Calderys is there to help you to select the best refractory solutions for your aluminium top charging melting furnace (also known as top loading furnace or round melting furnace). Our objective is to provide peace of mind to the production team with proven quality refractory linings and high thermal insulation performance. Corundum growth in walls and on burner quarls, mechanical erosion of the bottom hearth, upper ring and door surrounds, degradation of the roof are typical issues that Calderys will solve in partnership with you. From fast repairs to full furnace refractory relining, contact us (and ask your sales representative for our targeted brochure on the top charging furnace).

From monolithics to refractory expertise, Calderys is there to help you to select the best refractory solutions for your aluminium top charging melting furnace (also known as top loading furnace or round melting furnace). Our objective is to provide peace of mind to the production team with proven quality refractory linings and high thermal insulation performance. Corundum growth in walls and on burner quarls, mechanical erosion of the bottom hearth, upper ring and door surrounds, degradation of the roof are typical issues that Calderys will solve in partnership with you. From fast repairs to full furnace refractory relining, contact us (and ask your sales representative for our targeted brochure on the top charging furnace).