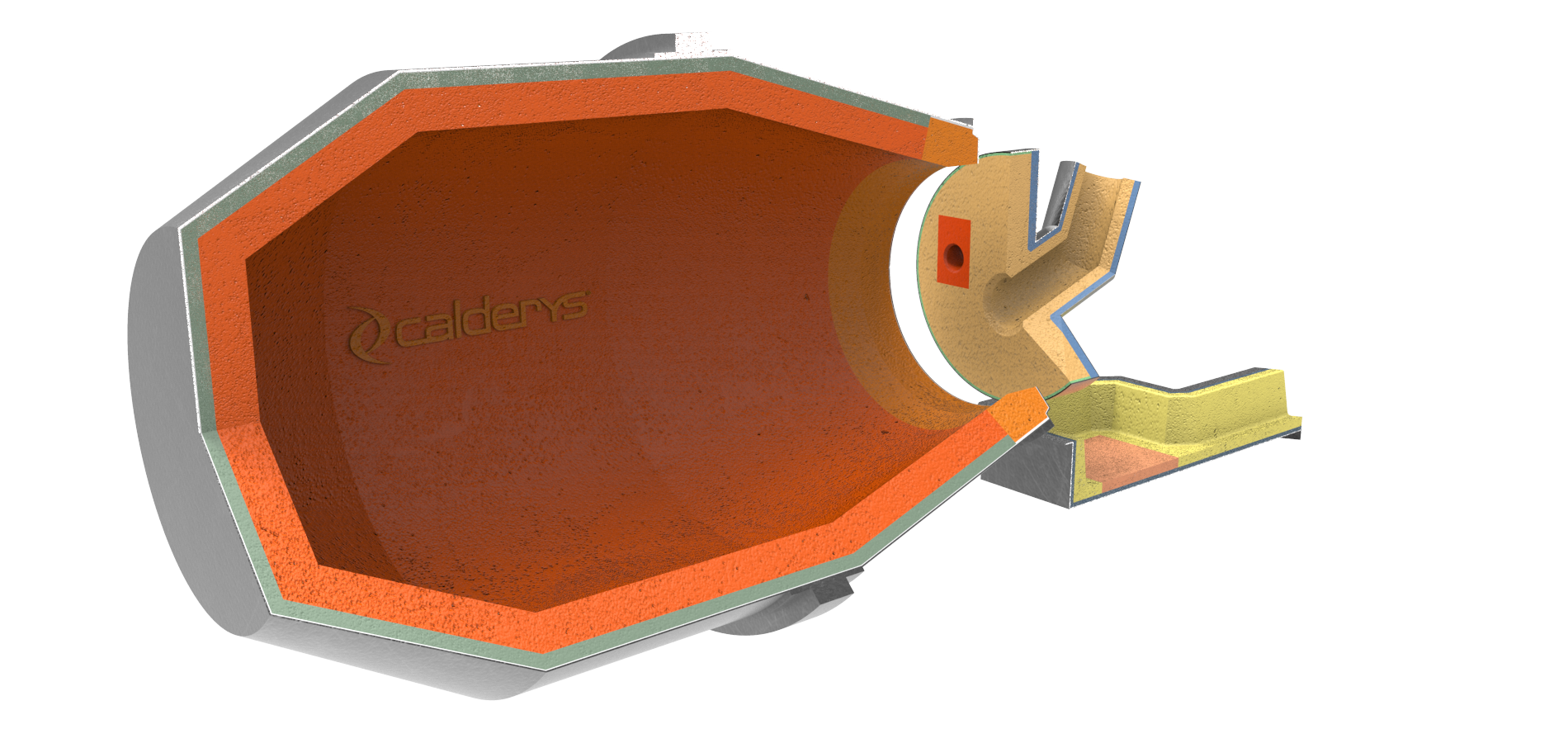

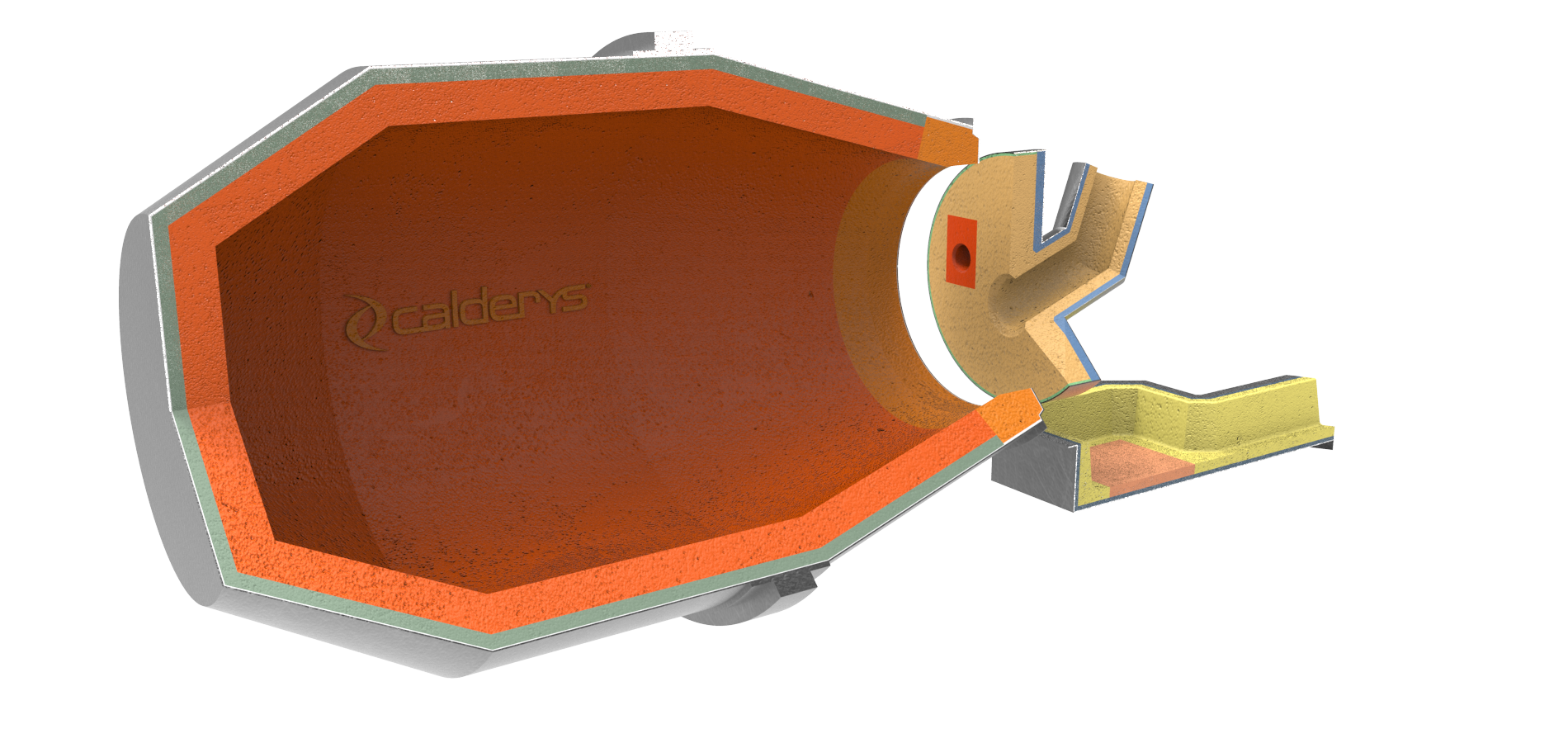

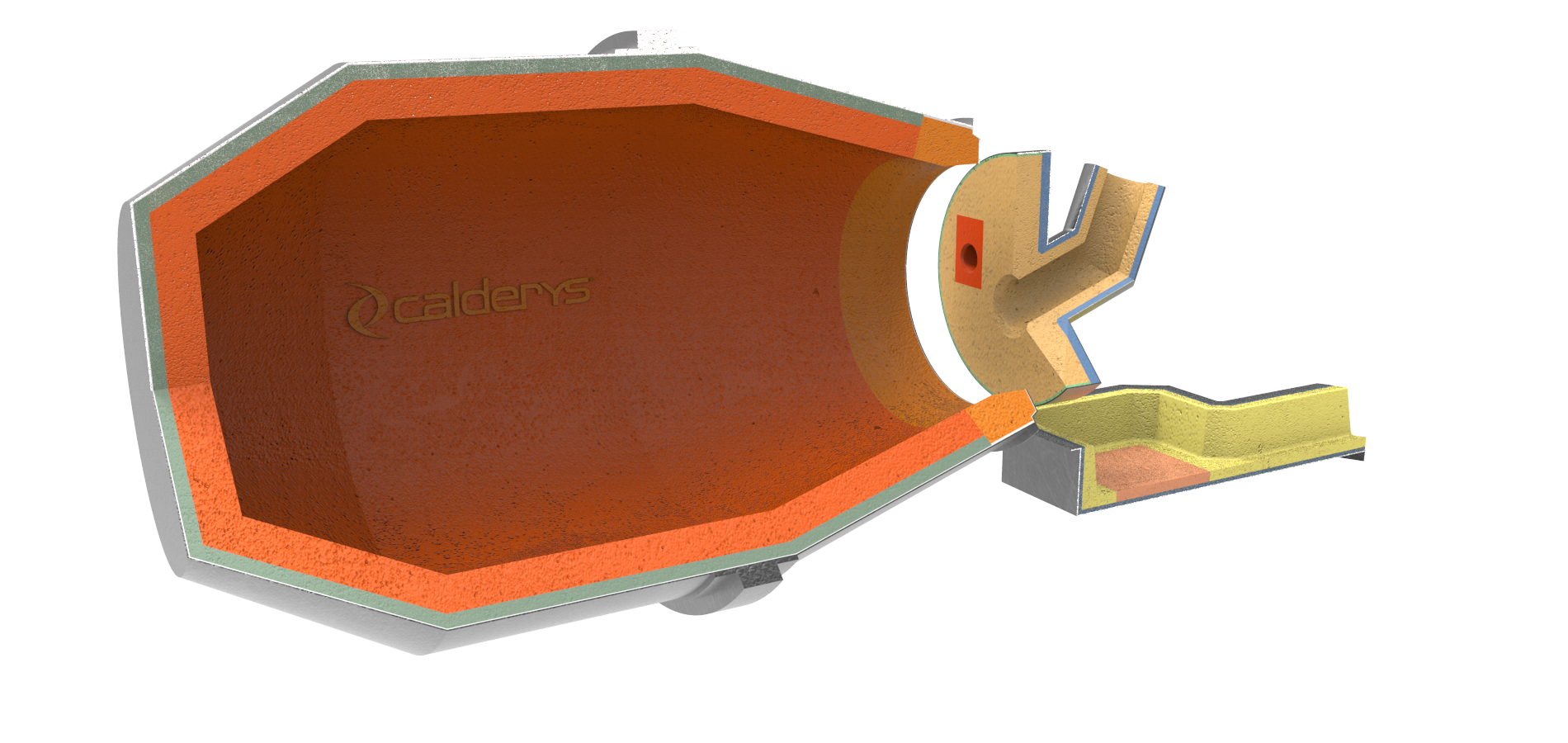

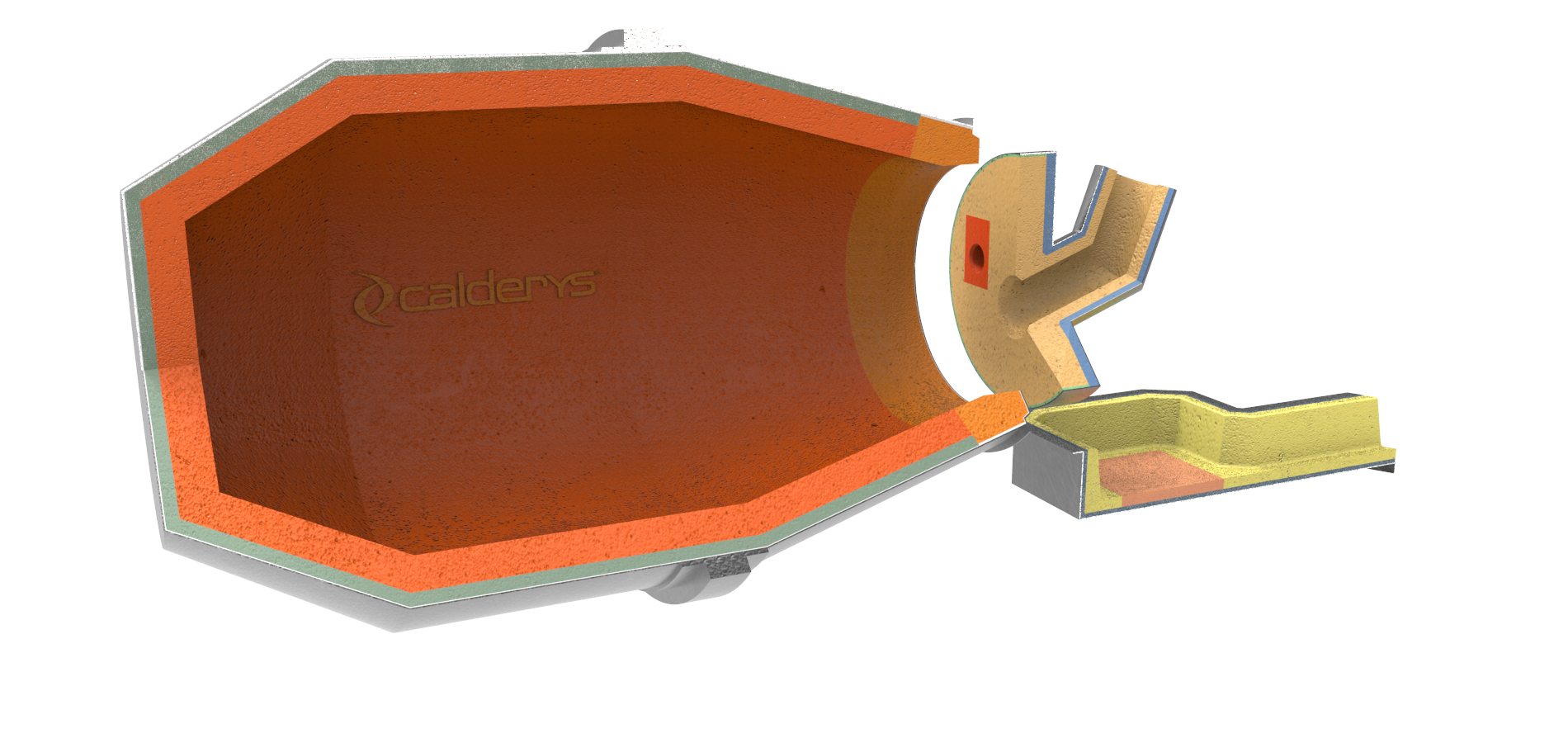

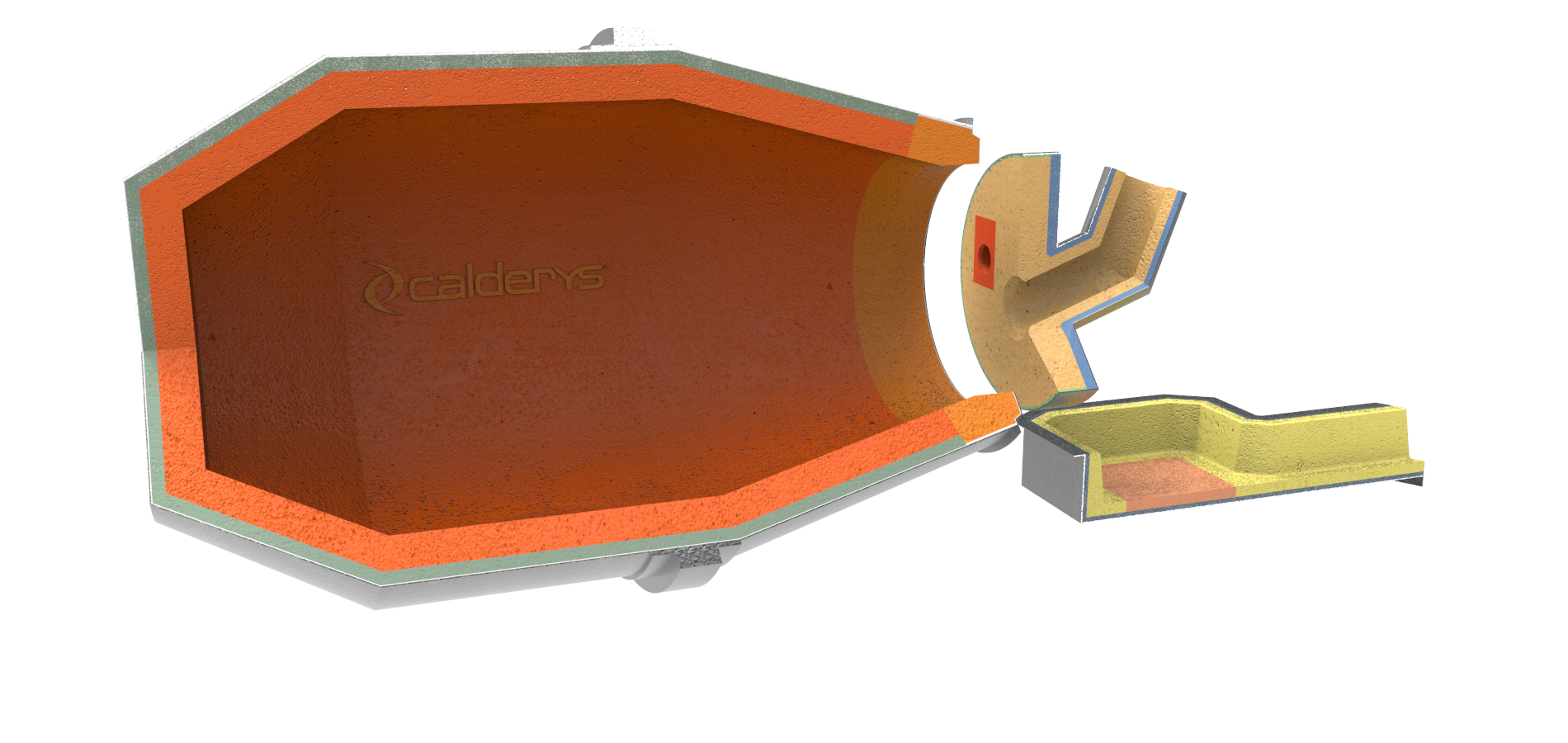

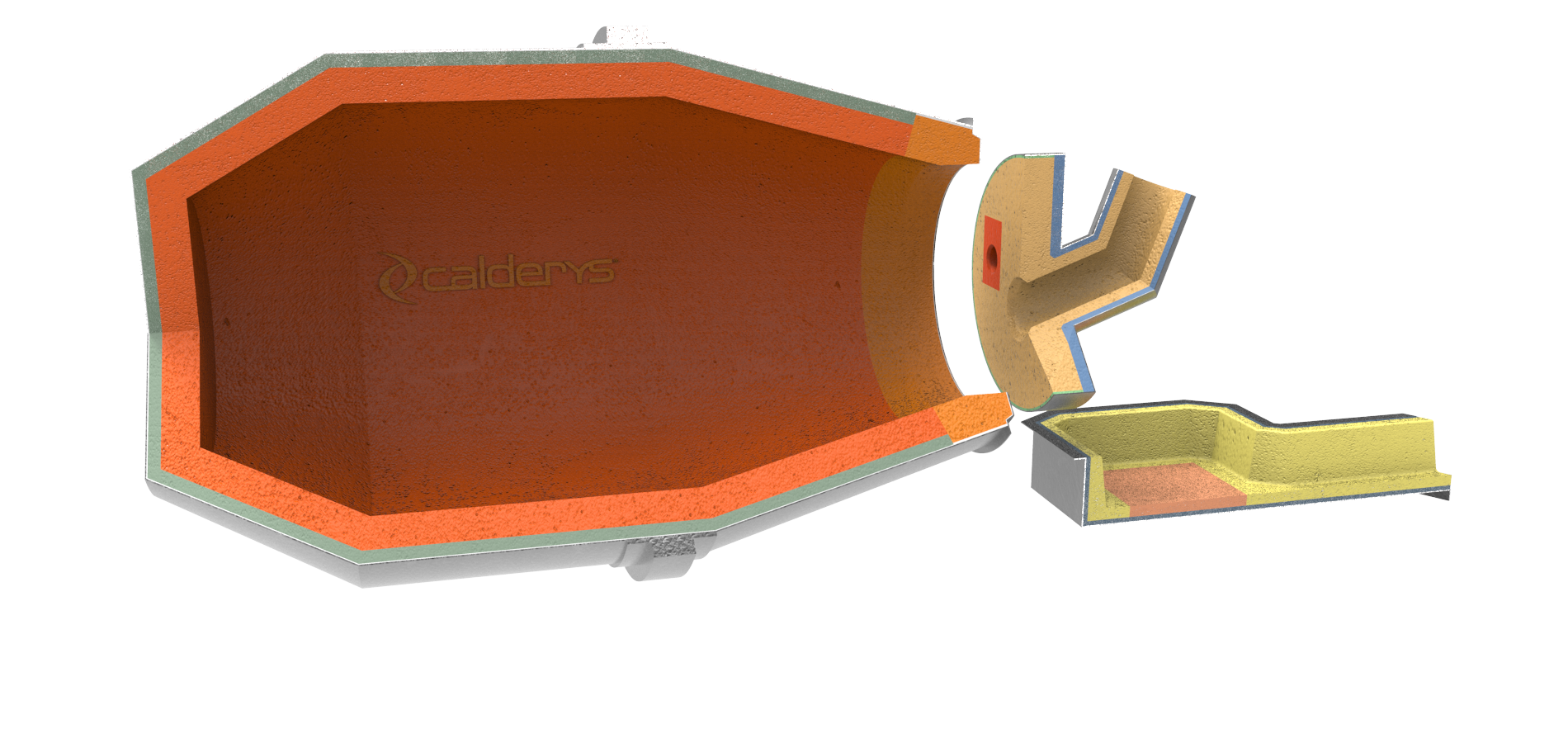

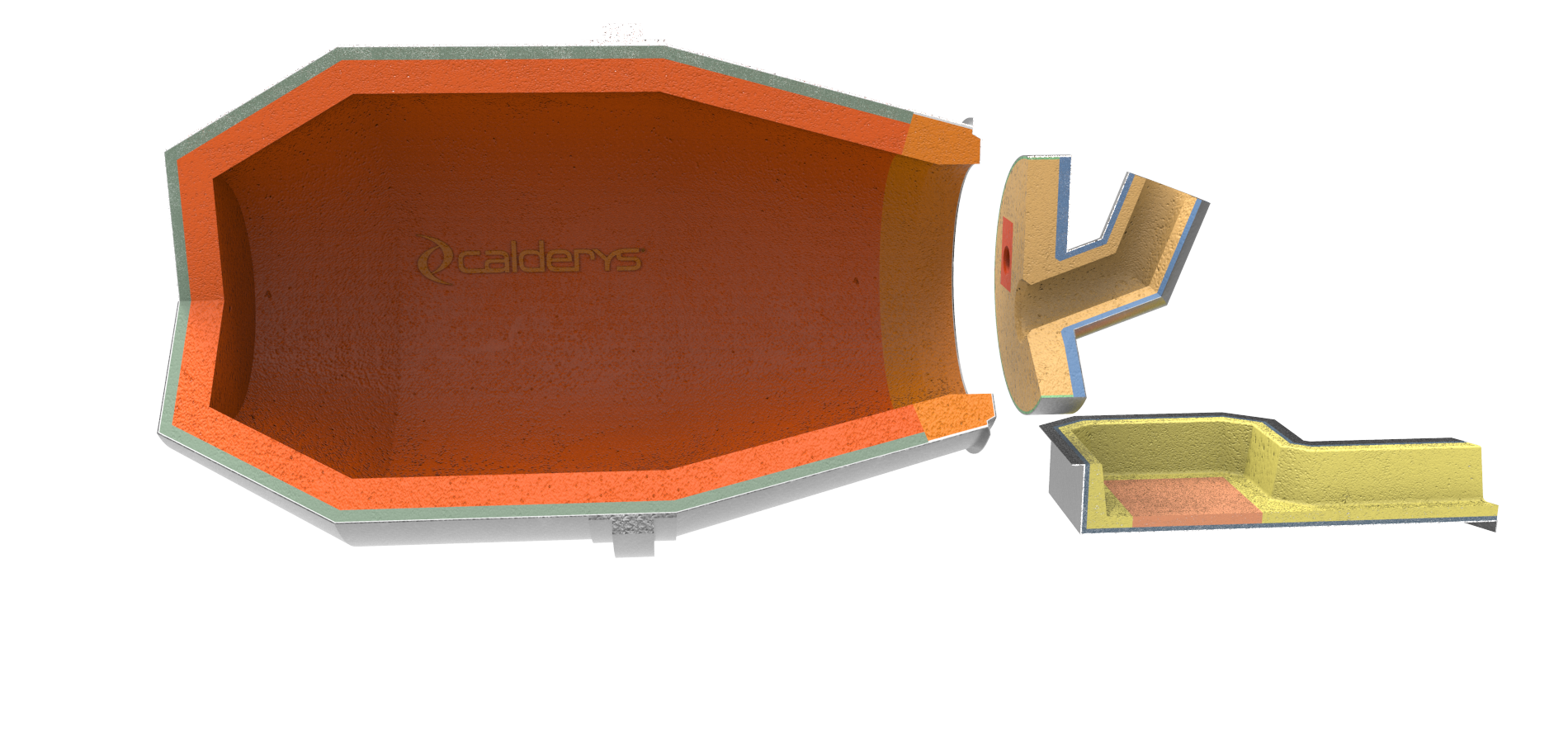

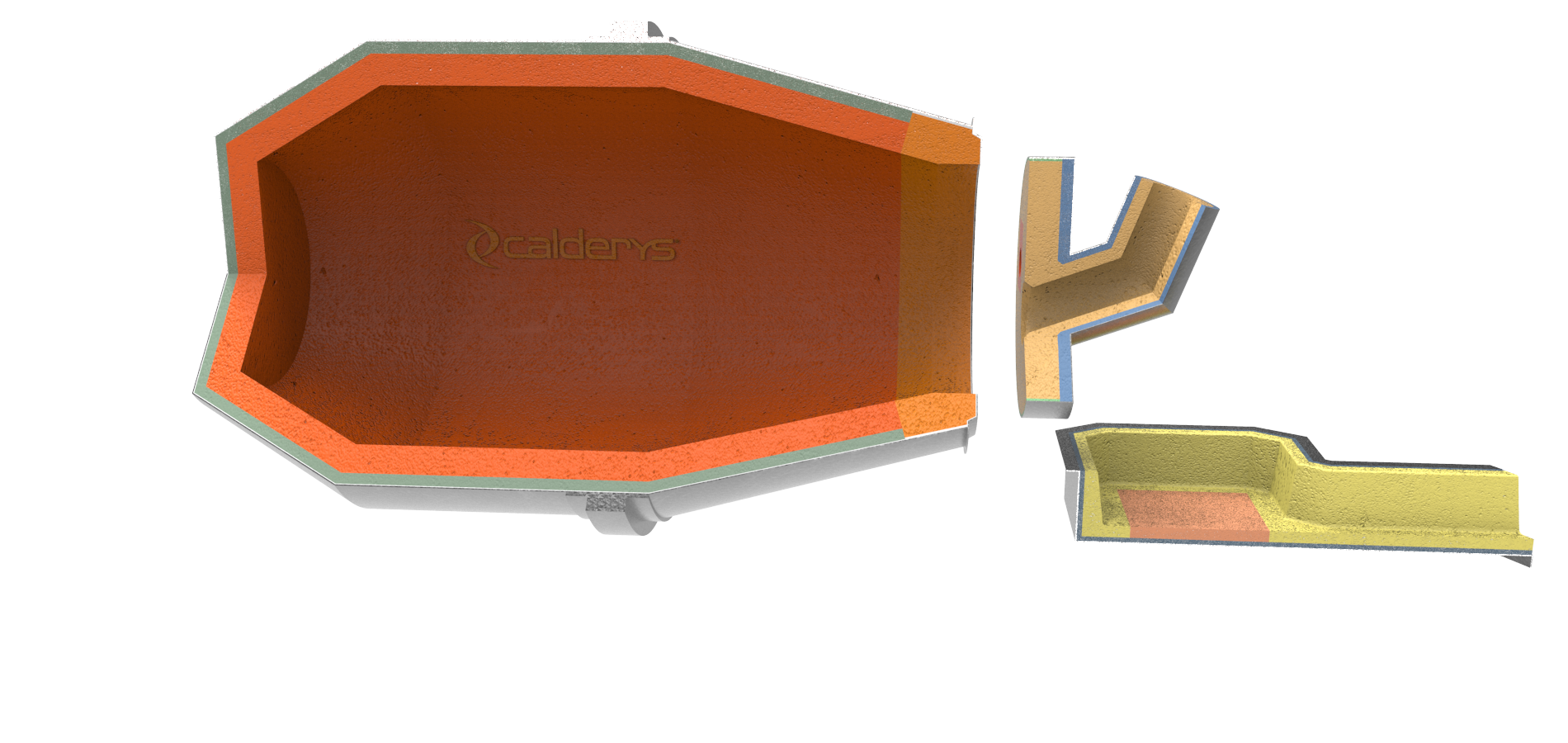

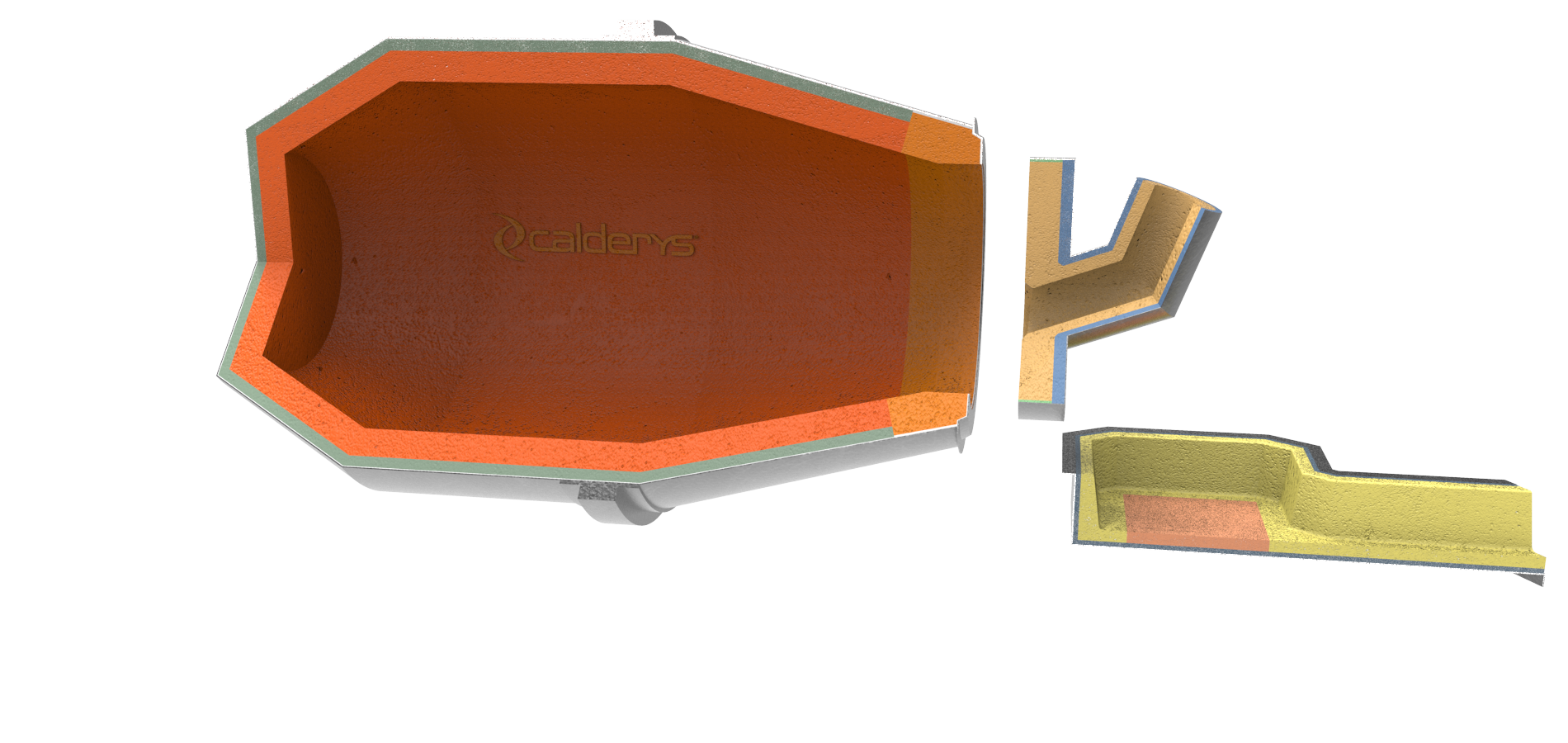

Rotary Furnace

This furnace is used for melting aluminium scrap of all types (dirty scrap, borings, etc.) so the refractory solution depends a lot on the salt level of the liquid metal. Another important factor when deciding on your refractory lining is abrasion resistance of both the charge itself and of the cleaning tools.

This furnace is used for melting aluminium scrap of all types (dirty scrap, borings, etc.) so the refractory solution depends a lot on the salt level of the liquid metal. Another important factor when deciding on your refractory lining is abrasion resistance of both the charge itself and of the cleaning tools.

Monolithic refractories are normally in balance with bricks, so please consult with our Calderys experts on the ideal composition for your production process and to receive a dedicated brochure on the rotary furnace for Aluminium.