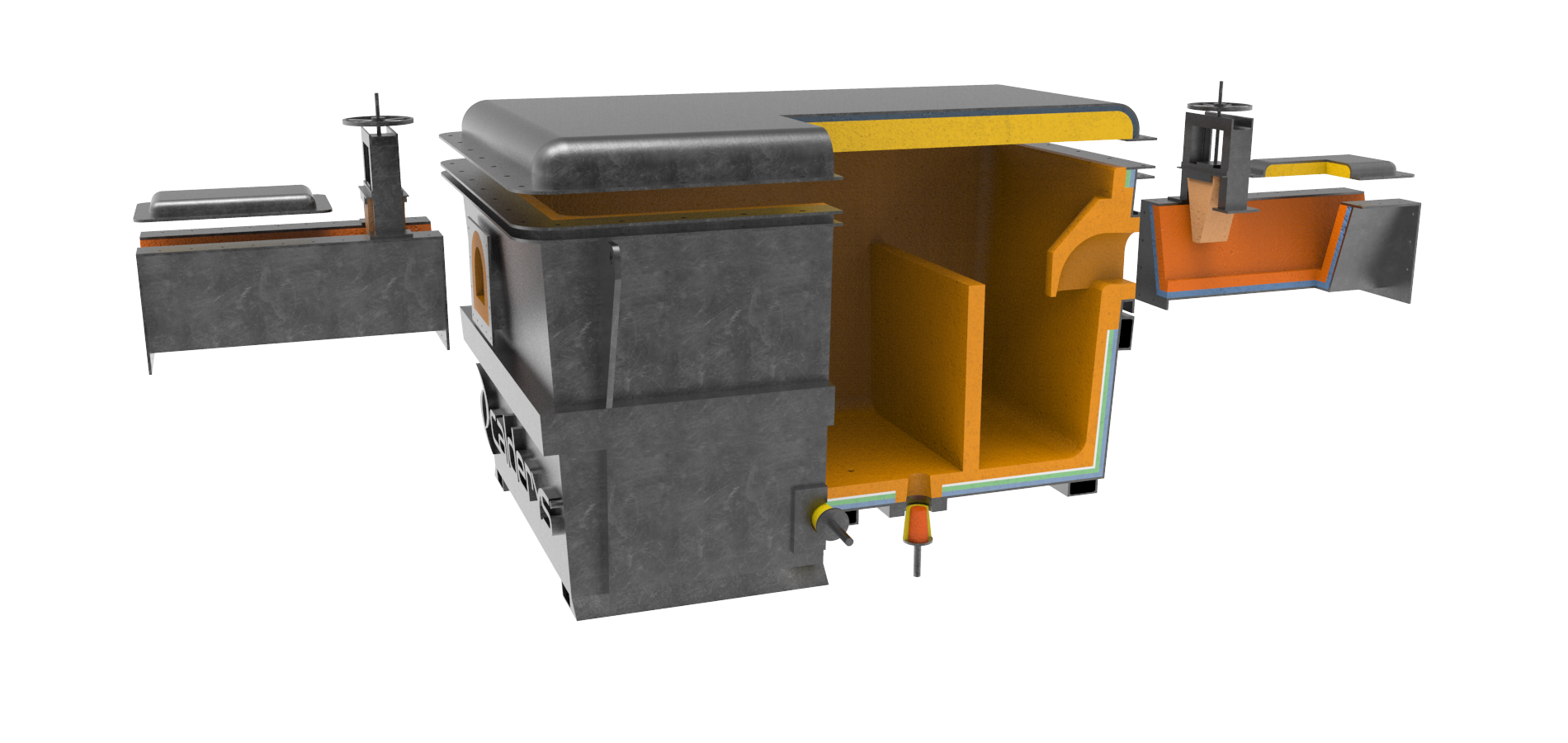

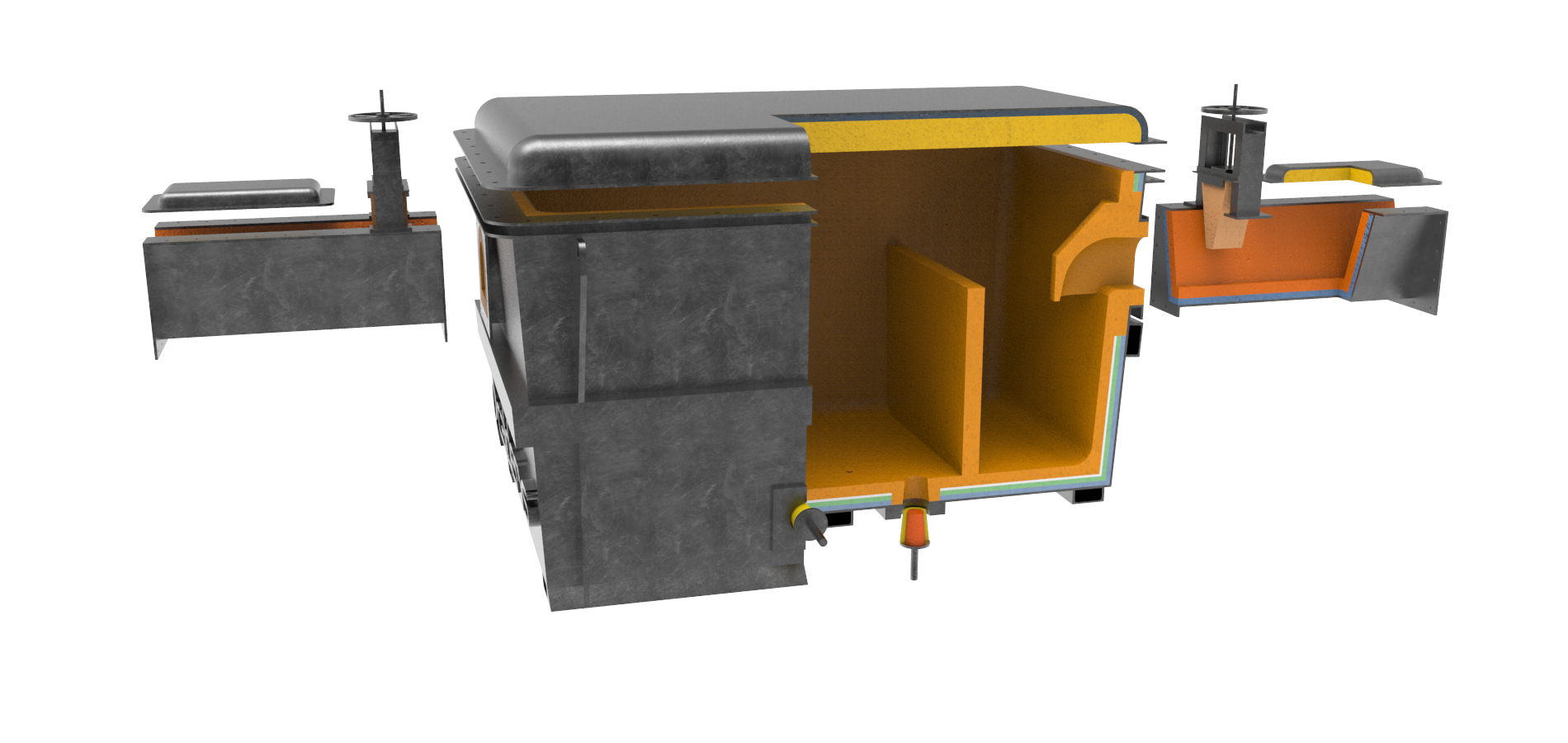

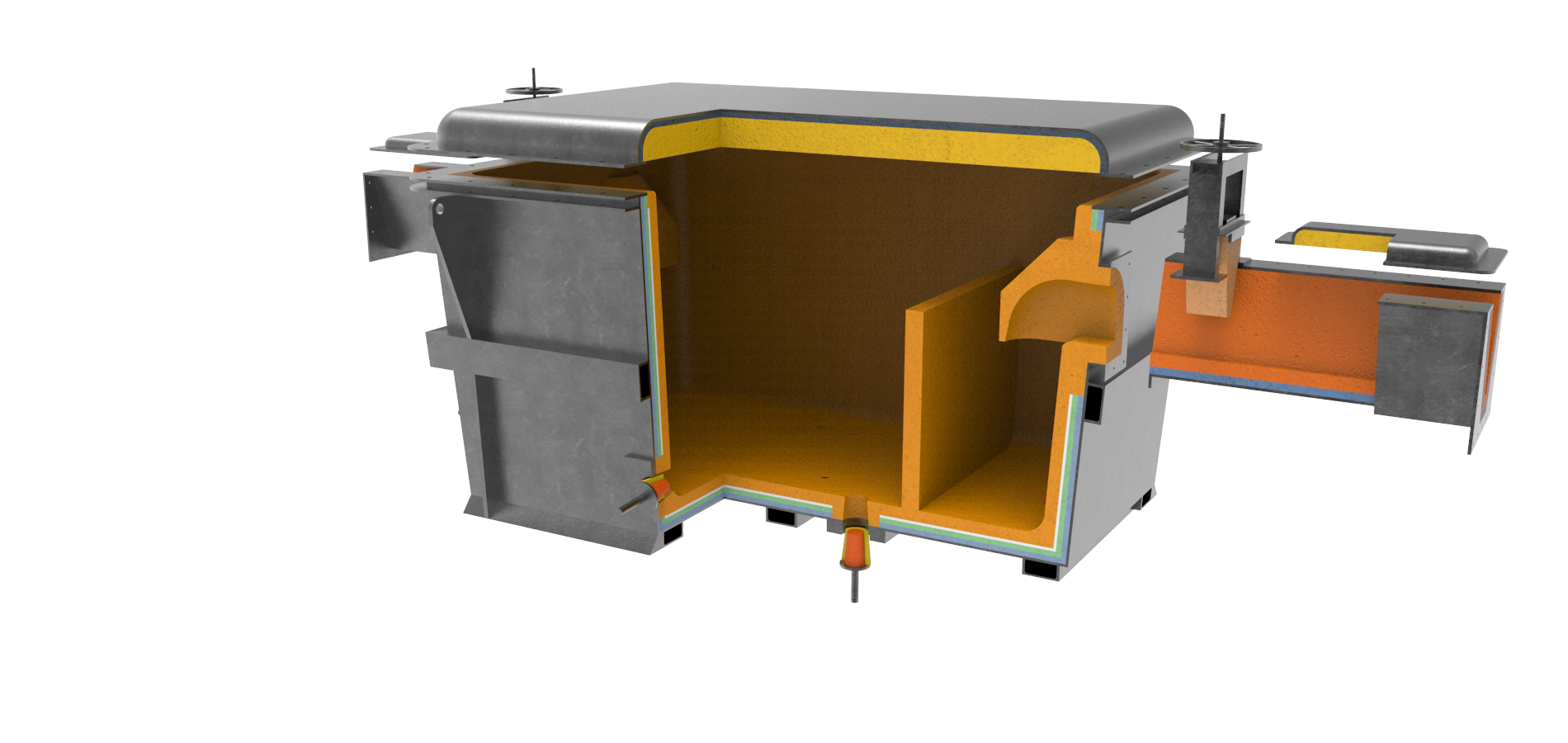

Runners & Treatment Box

For this Aluminium foundry area, Calderys is focused on providing you with the highest metal quality by offering refractory solutions for zero metal impurities and chemical pick-up. To avoid hydrogen pick-up, Calderys experts recommend precast (ready-shape) or in-house equipment lining using our trusted monolithic refractories for the most immediate and efficient servicing.

For this Aluminium foundry area, Calderys is focused on providing you with the highest metal quality by offering refractory solutions for zero metal impurities and chemical pick-up. To avoid hydrogen pick-up, Calderys experts recommend precast (ready-shape) or in-house equipment lining using our trusted monolithic refractories for the most immediate and efficient servicing.

Calderys refractories are designed specifically for liquid aluminium contact with the goal of increasing your equipment lifetime. Key benefits include:

- Resistance to corrosion

- Minimal metal temperature loss

- High mechanical resistance in balance with strong thermal insulation

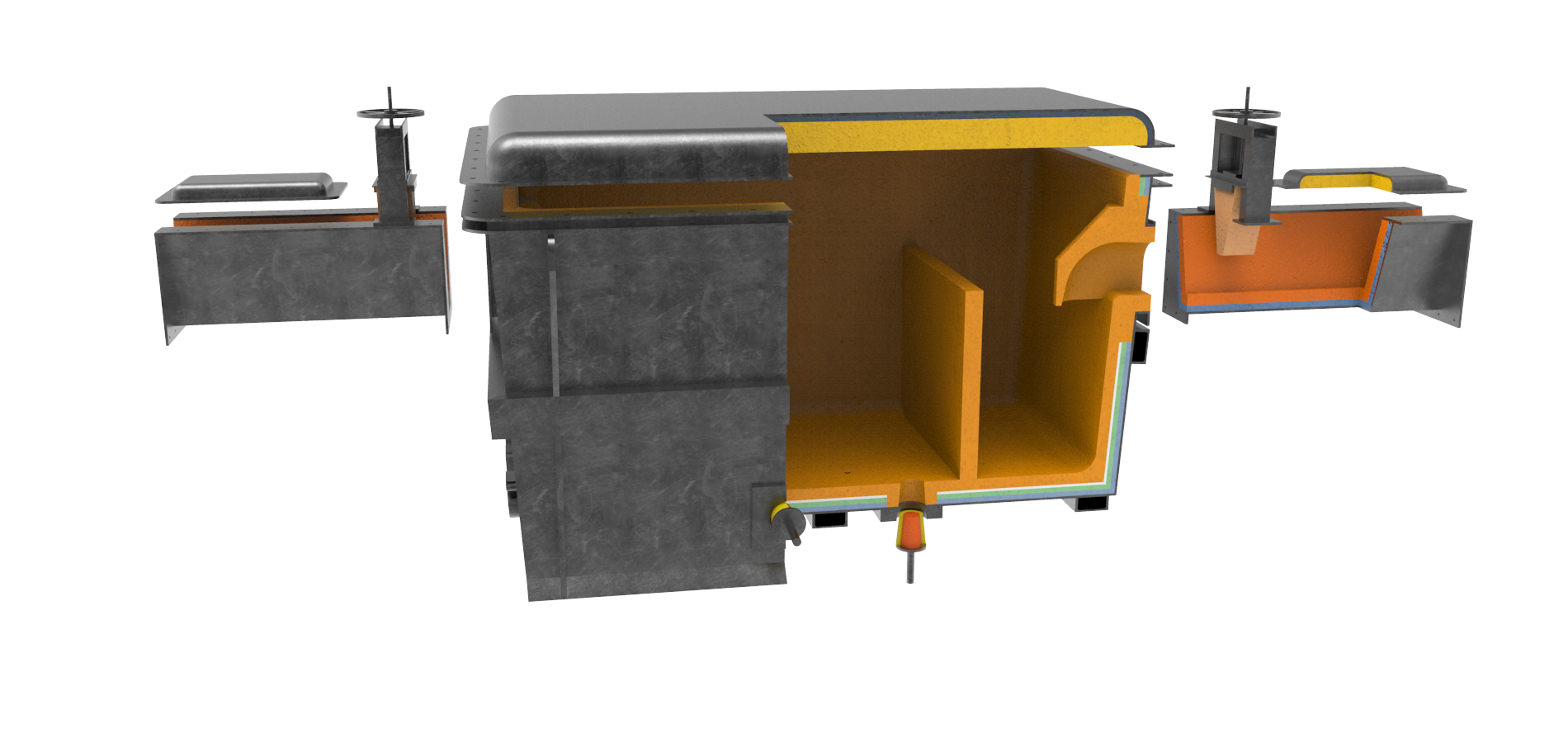

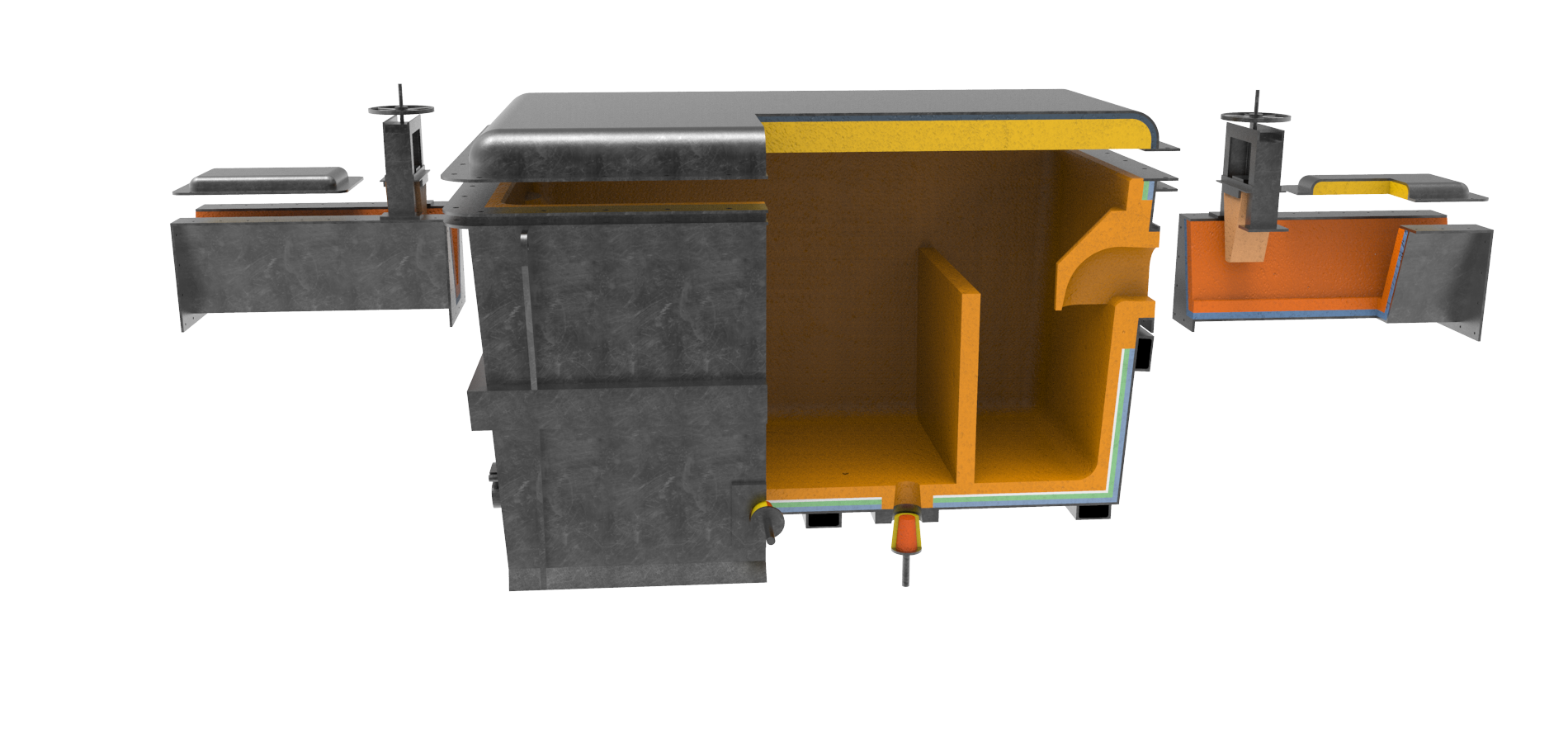

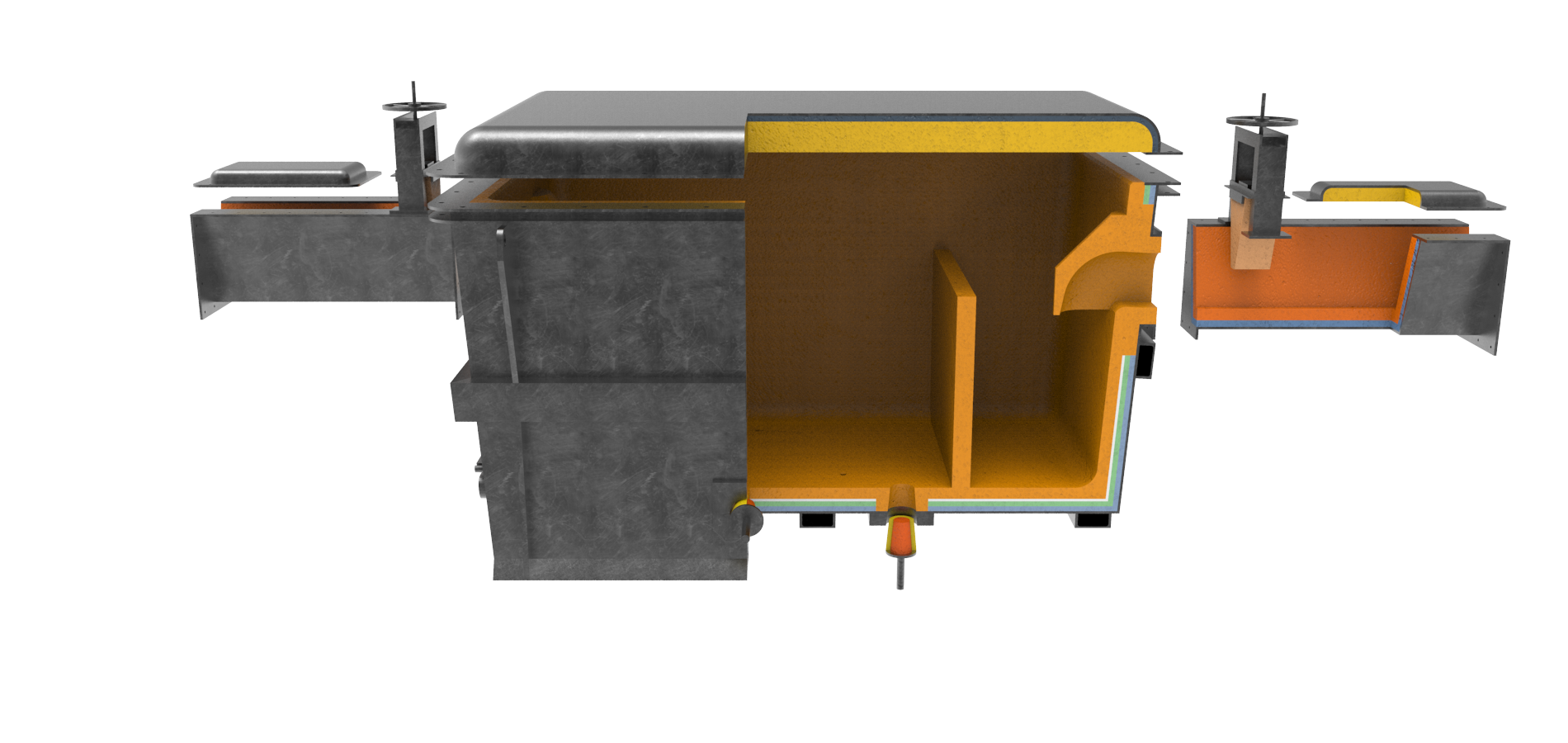

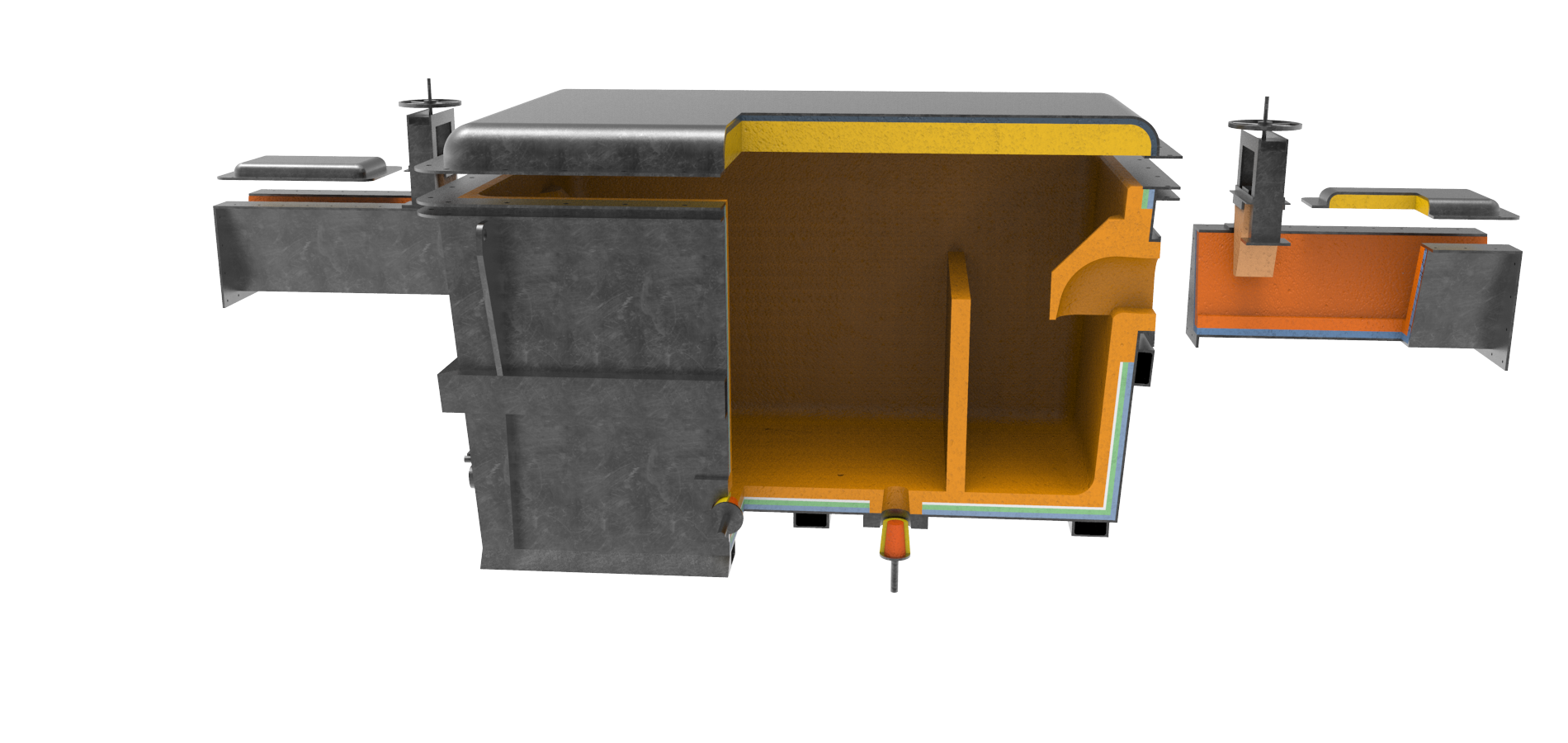

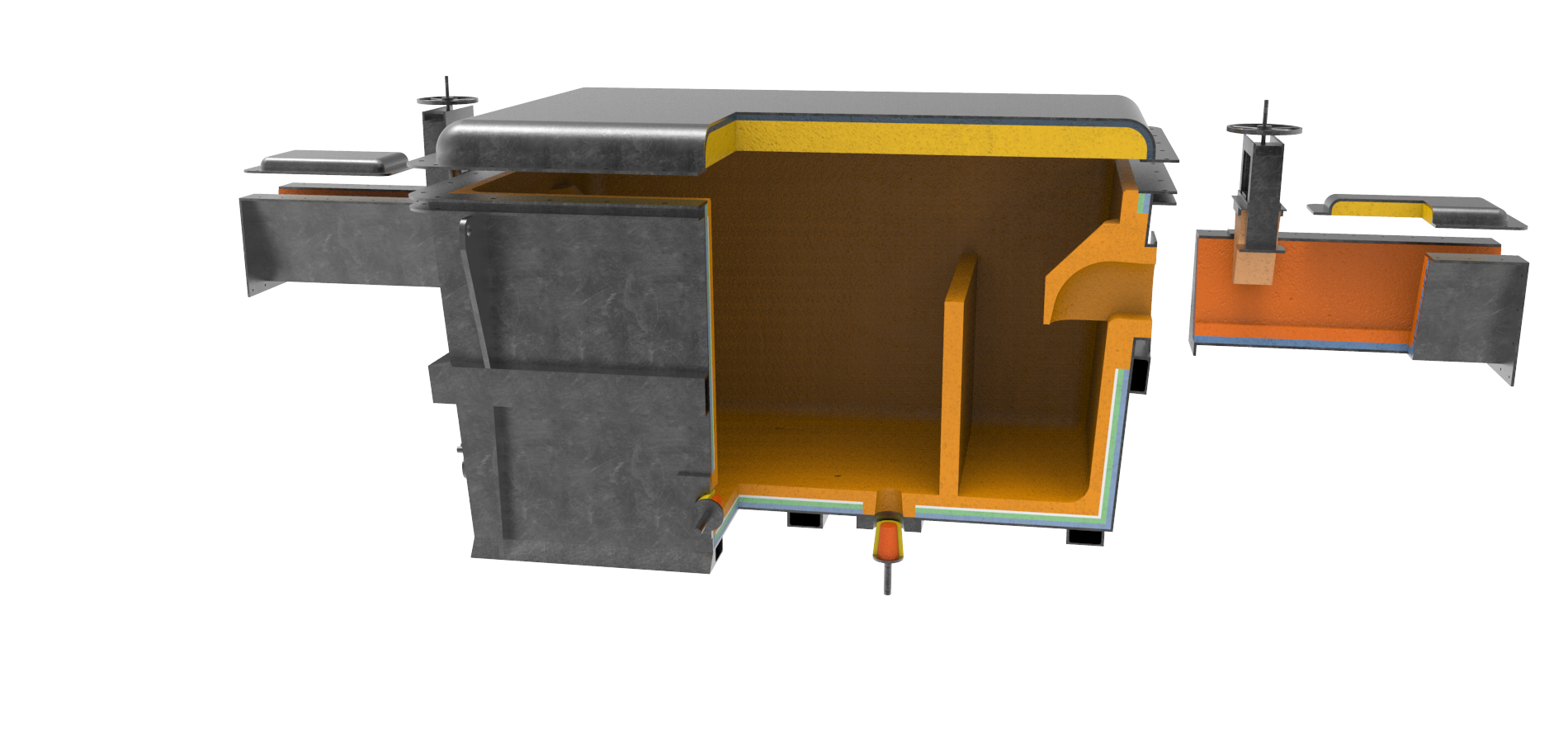

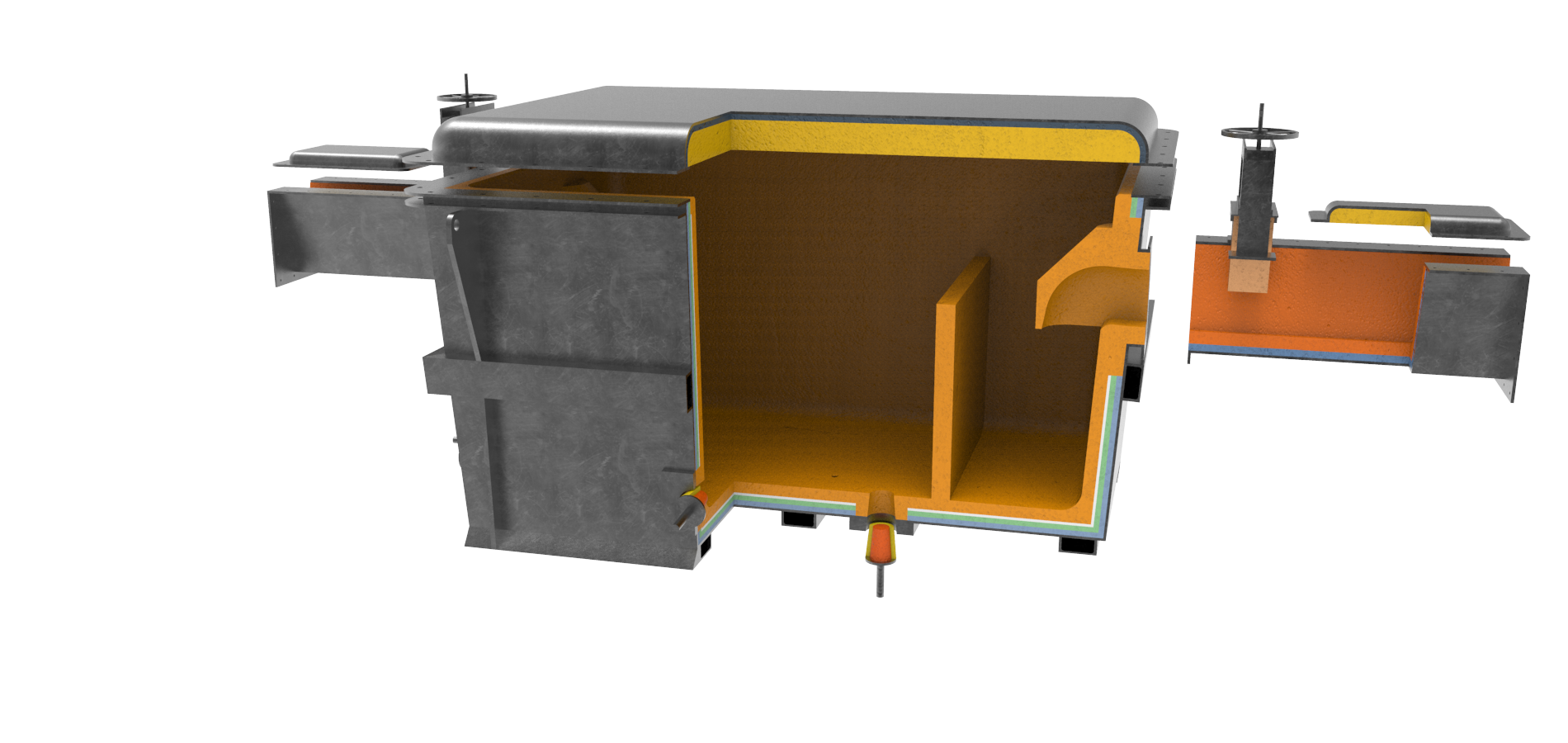

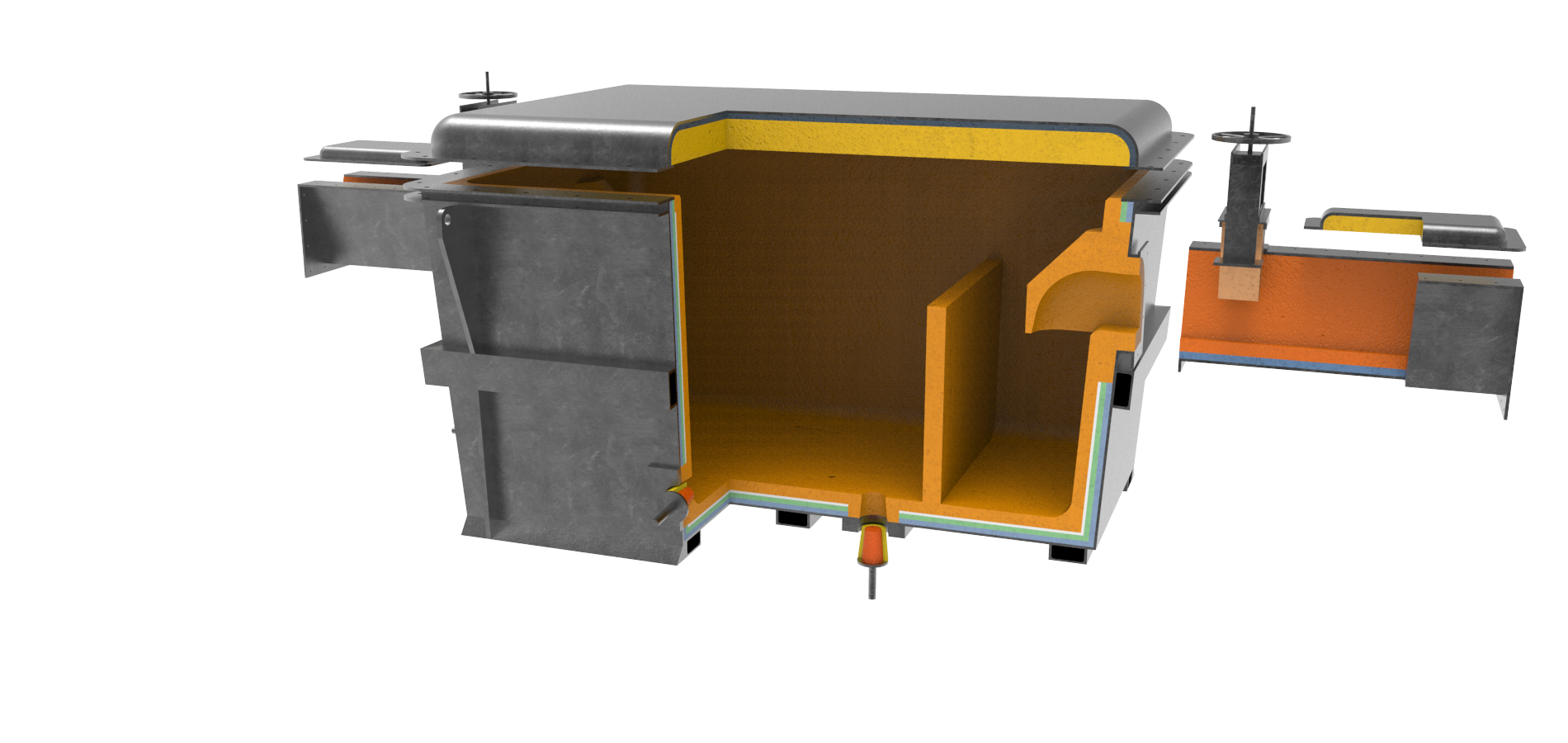

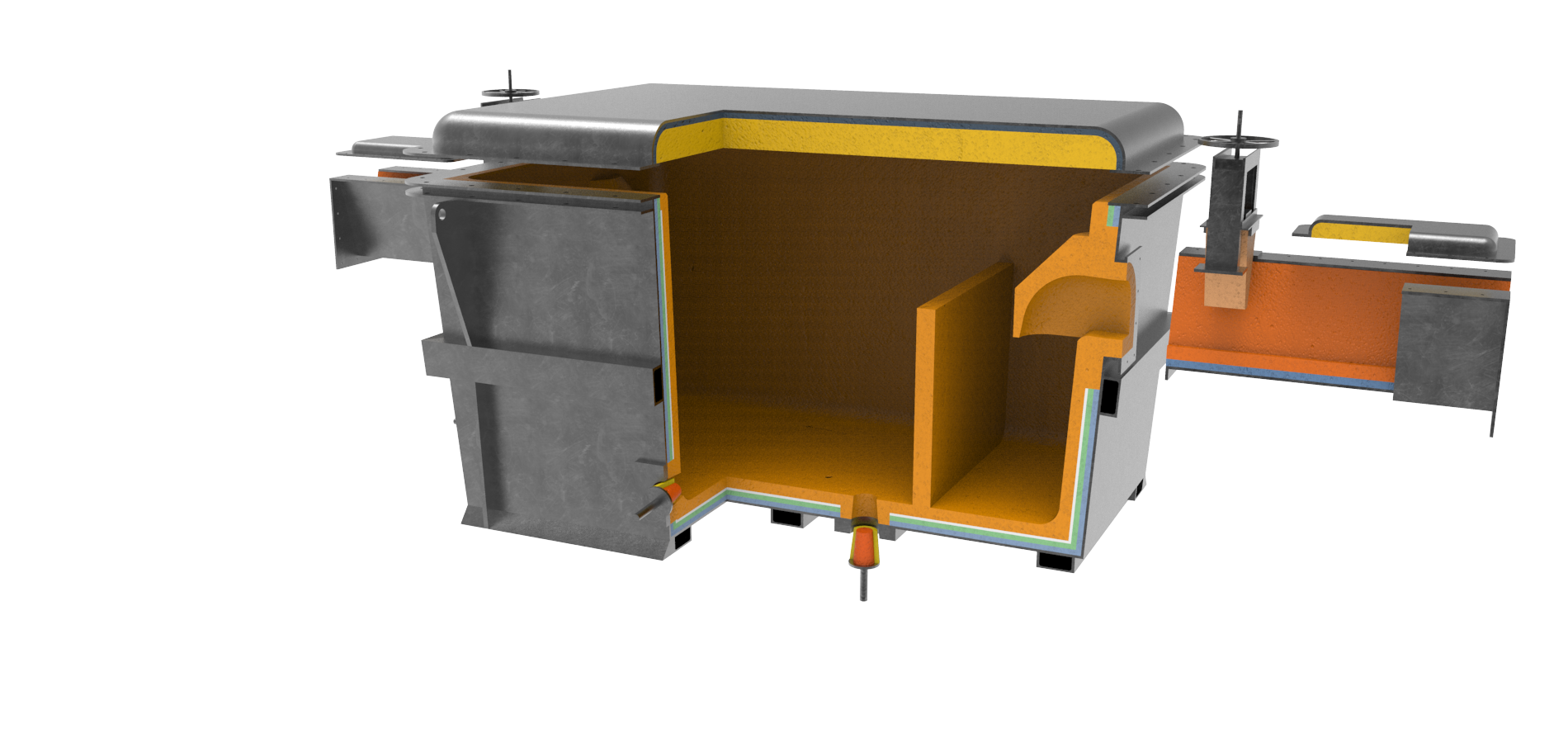

Our experts will recommend to you the ideal refractory options for all equipment zones (see full details on 3D drawing below), including: Runners or trough, Dam, Weir, Filter box, degassing box, casting table, treatment box, purging plug, and the cover or lid. For the runners in particular, Calderys ensures thermal expansion stability to avoid infiltration and preserve your production.

Please contact our refractory experts for further information and to request a specific brochure on the Aluminium runners and treatment box.