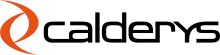

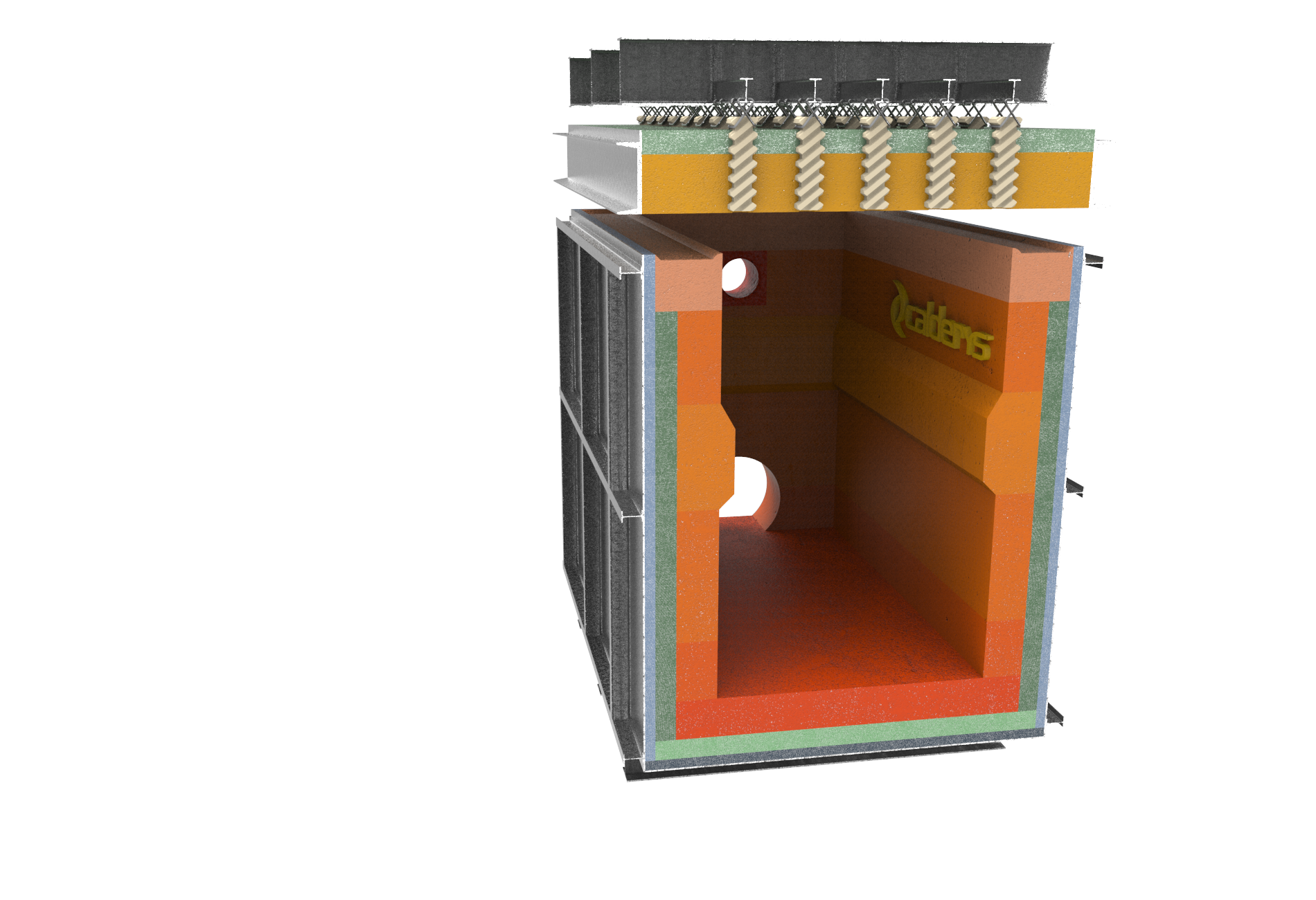

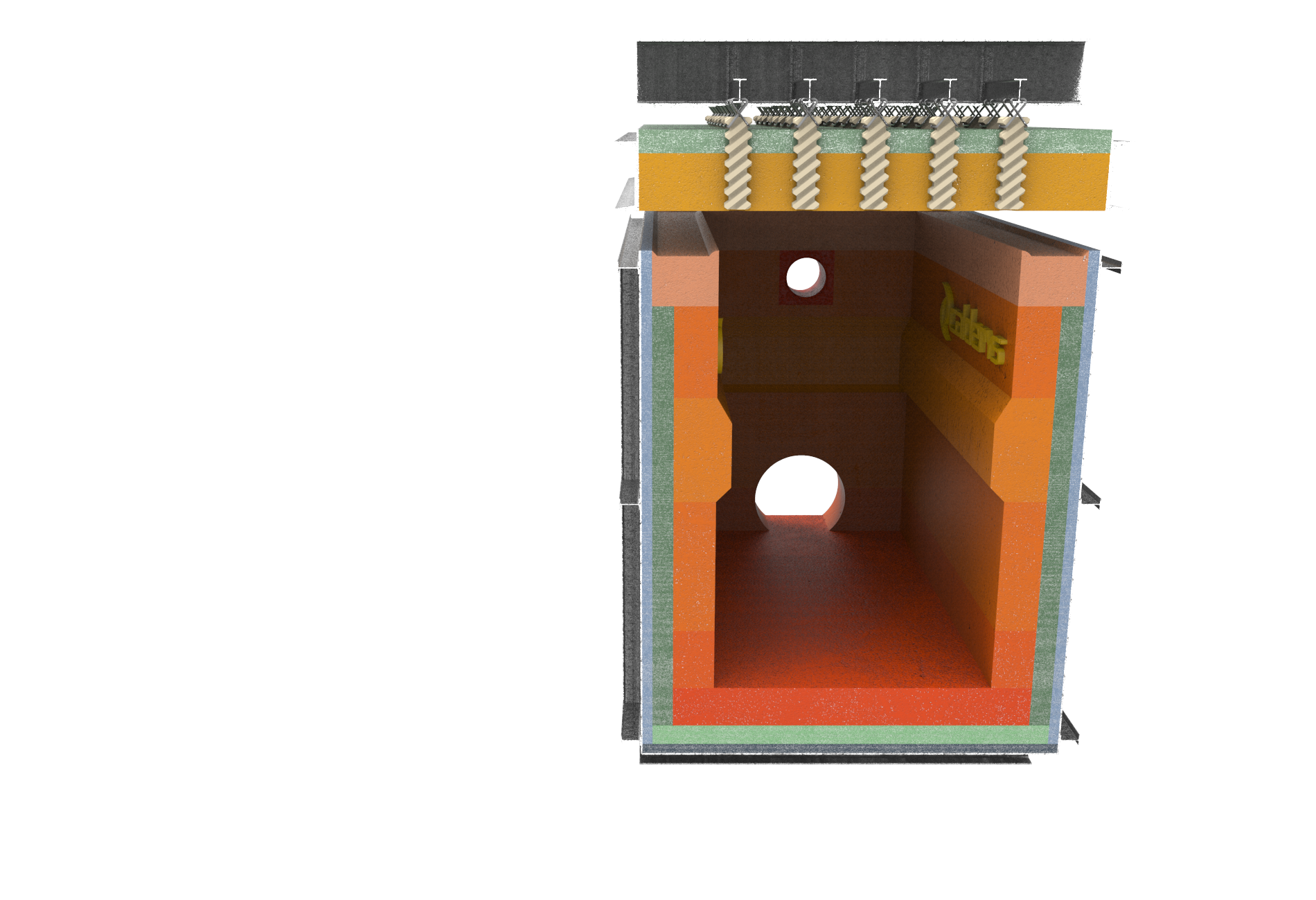

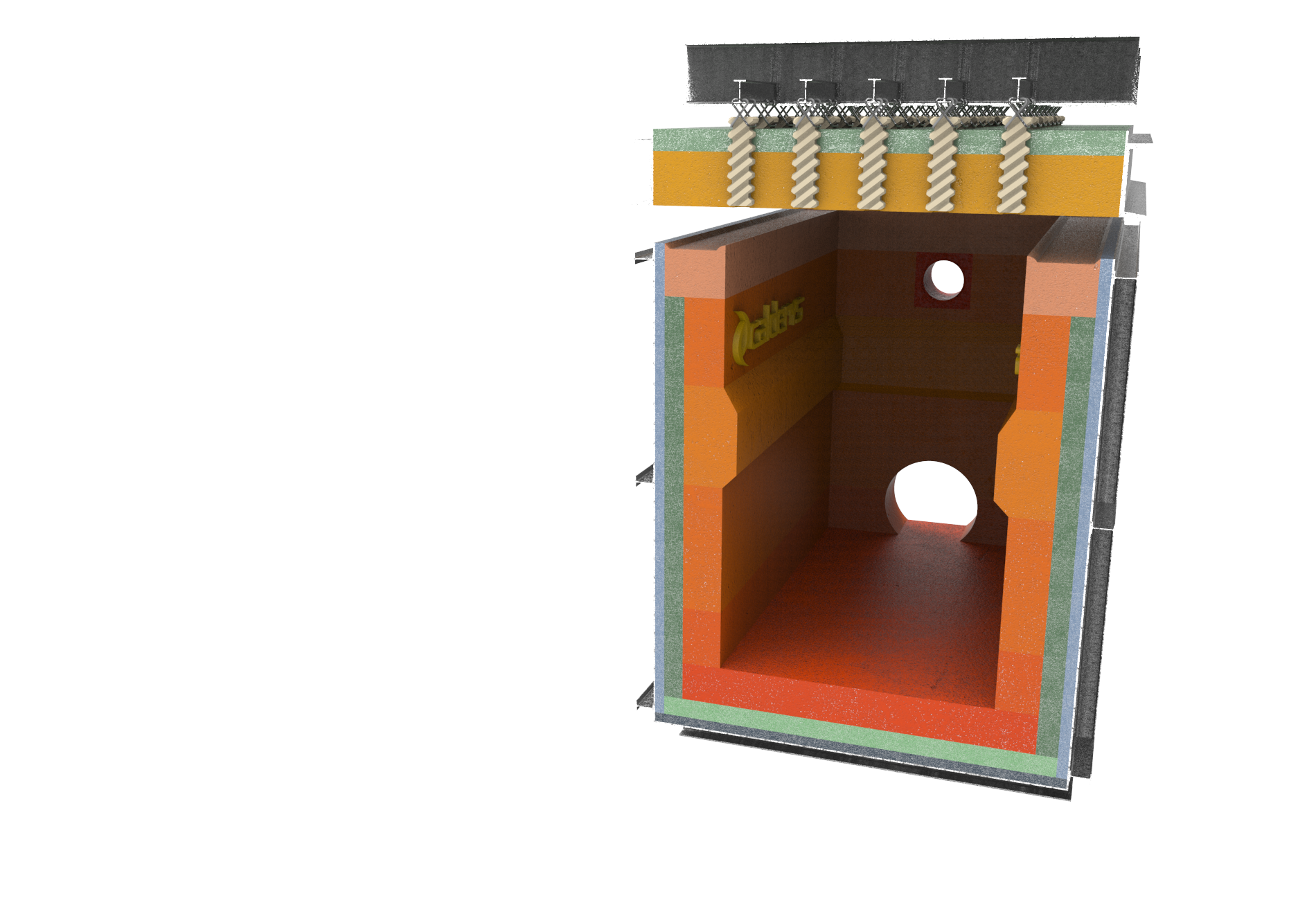

Soaking Pit Furnace

This furnace is for holding hot steel ingots to equalize their temperature before they are hot-rolled in a steel-making or rolling mill complex. Normal practice is to charge ingots into the soaking pits immediately after stripping from the moulds whilst they are still hot. Soaking pit temperatures are generally controlled at 1300°C. Each pit may hold several ingots and serves to bring the ingots up to a uniform temperature for rolling and to act as a reservoir to accommodate fluctuations in the flow of ingots.

This furnace is for holding hot steel ingots to equalize their temperature before they are hot-rolled in a steel-making or rolling mill complex. Normal practice is to charge ingots into the soaking pits immediately after stripping from the moulds whilst they are still hot. Soaking pit temperatures are generally controlled at 1300°C. Each pit may hold several ingots and serves to bring the ingots up to a uniform temperature for rolling and to act as a reservoir to accommodate fluctuations in the flow of ingots.

We conduct an extensive audit of your process to design a customised solution from the insulating castables, precast shapes and large range of ceramic anchors in our monolithics portfolio.