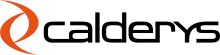

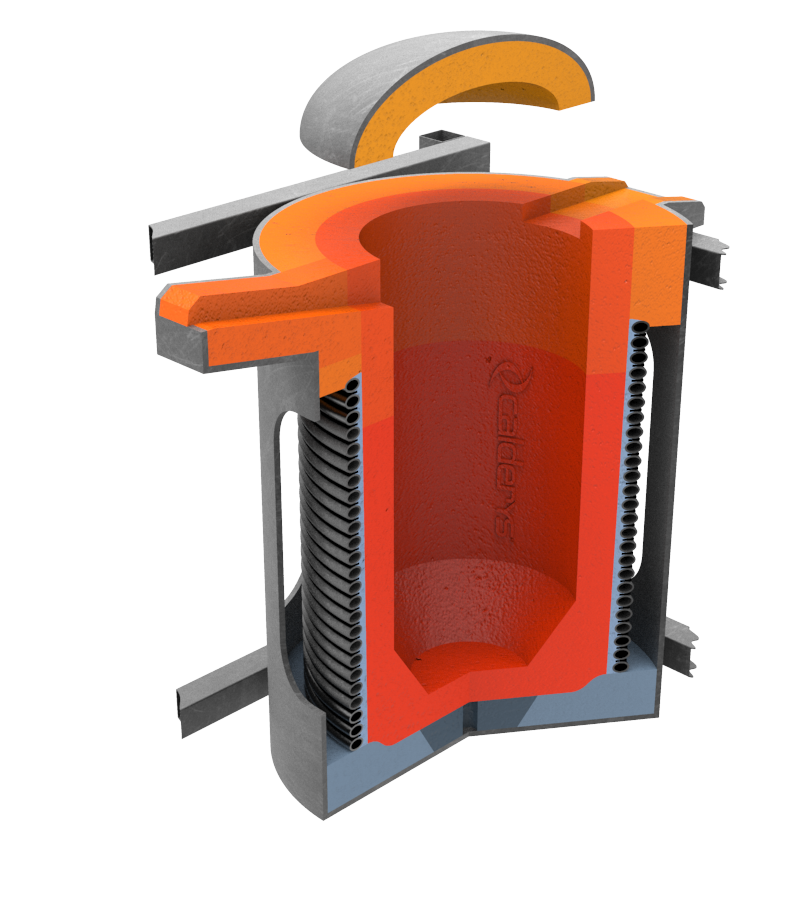

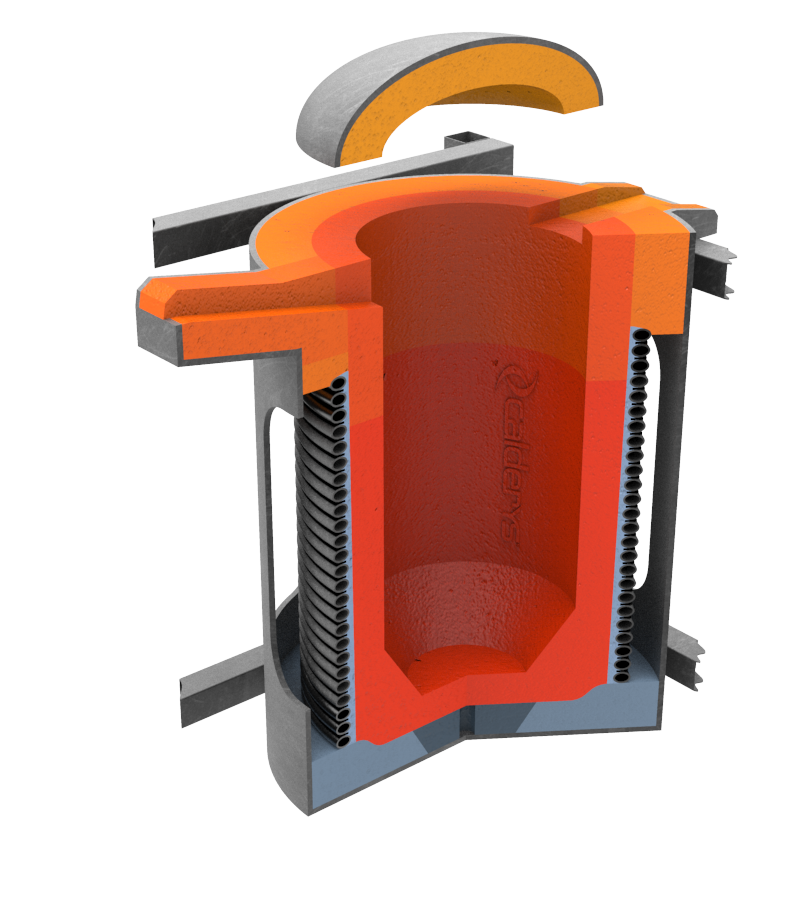

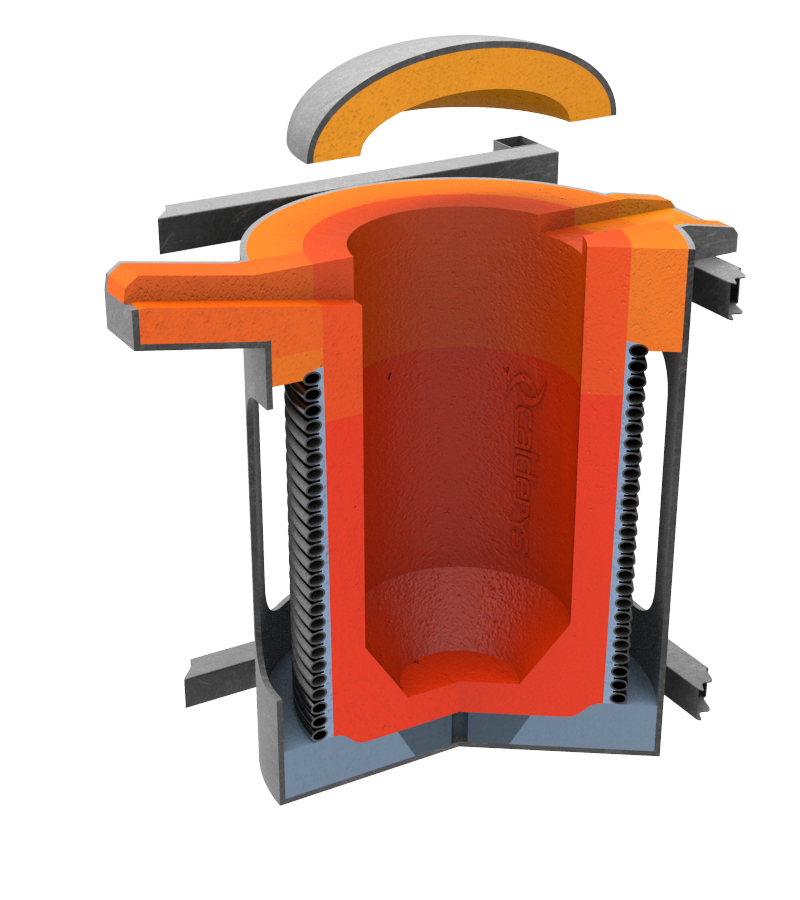

Coreless Induction Furnace (CIF)

Calderys offers refractory solutions for all parts of Coreless Induction Furnaces, whether you are melting non-ferrous alloys with melting points below 1000°C, to highly alloyed steels above 1800 °C. Dinosaur-state rotary furnaces are also covered by these product ranges. We deliver products that allow you to securely operate your furnaces over a designated period and keep maintenance on schedule.

Calderys offers refractory solutions for all parts of Coreless Induction Furnaces, whether you are melting non-ferrous alloys with melting points below 1000°C, to highly alloyed steels above 1800 °C. Dinosaur-state rotary furnaces are also covered by these product ranges. We deliver products that allow you to securely operate your furnaces over a designated period and keep maintenance on schedule.