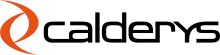

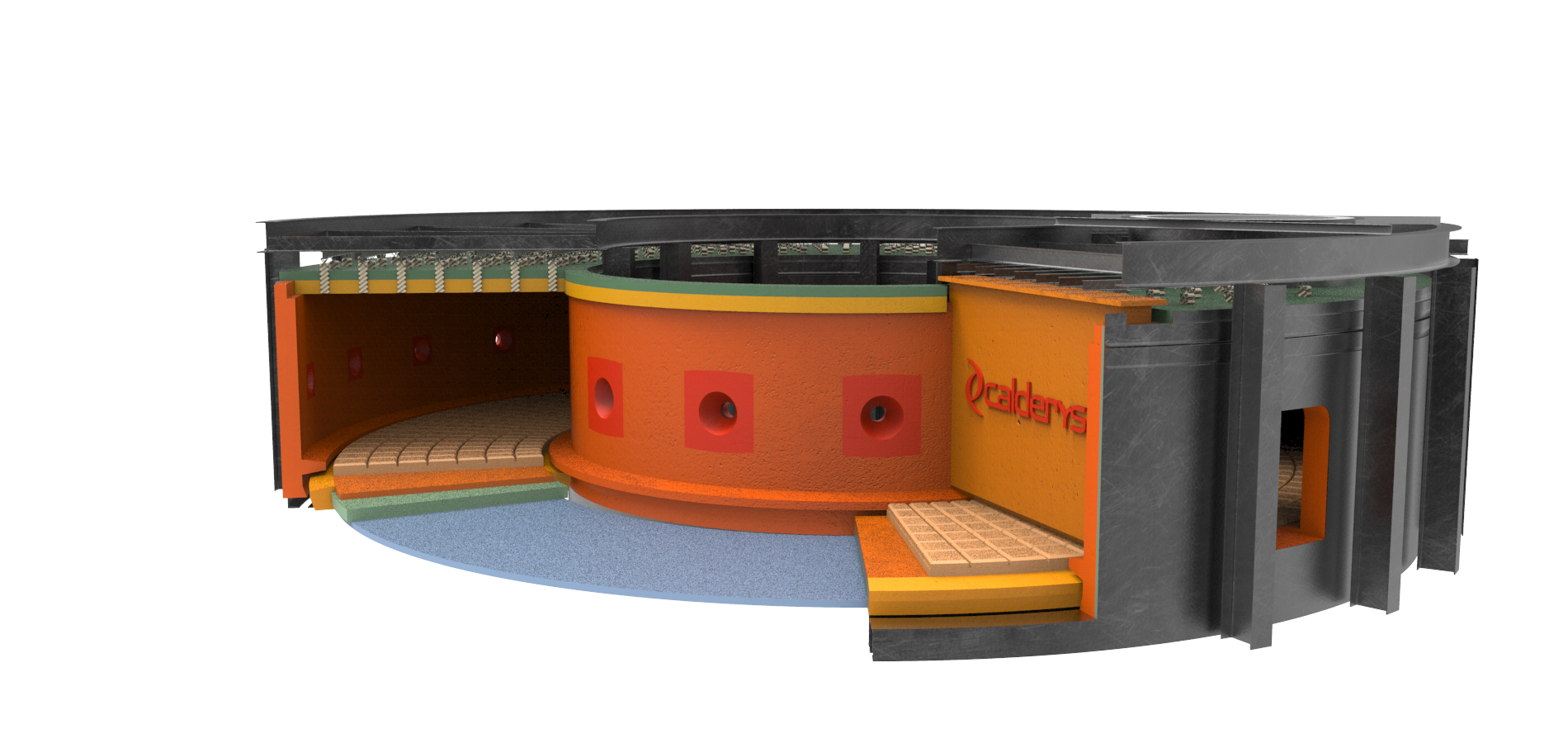

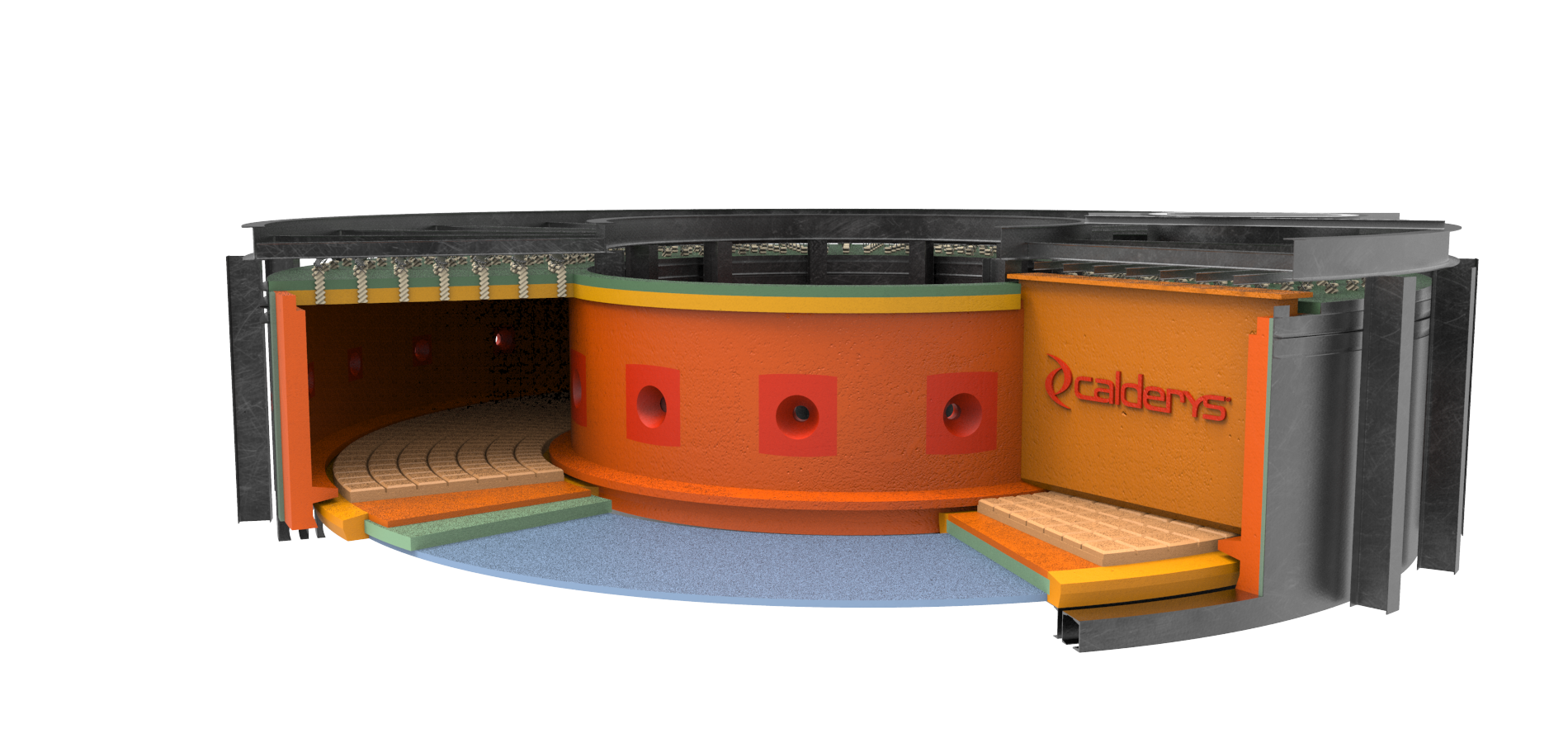

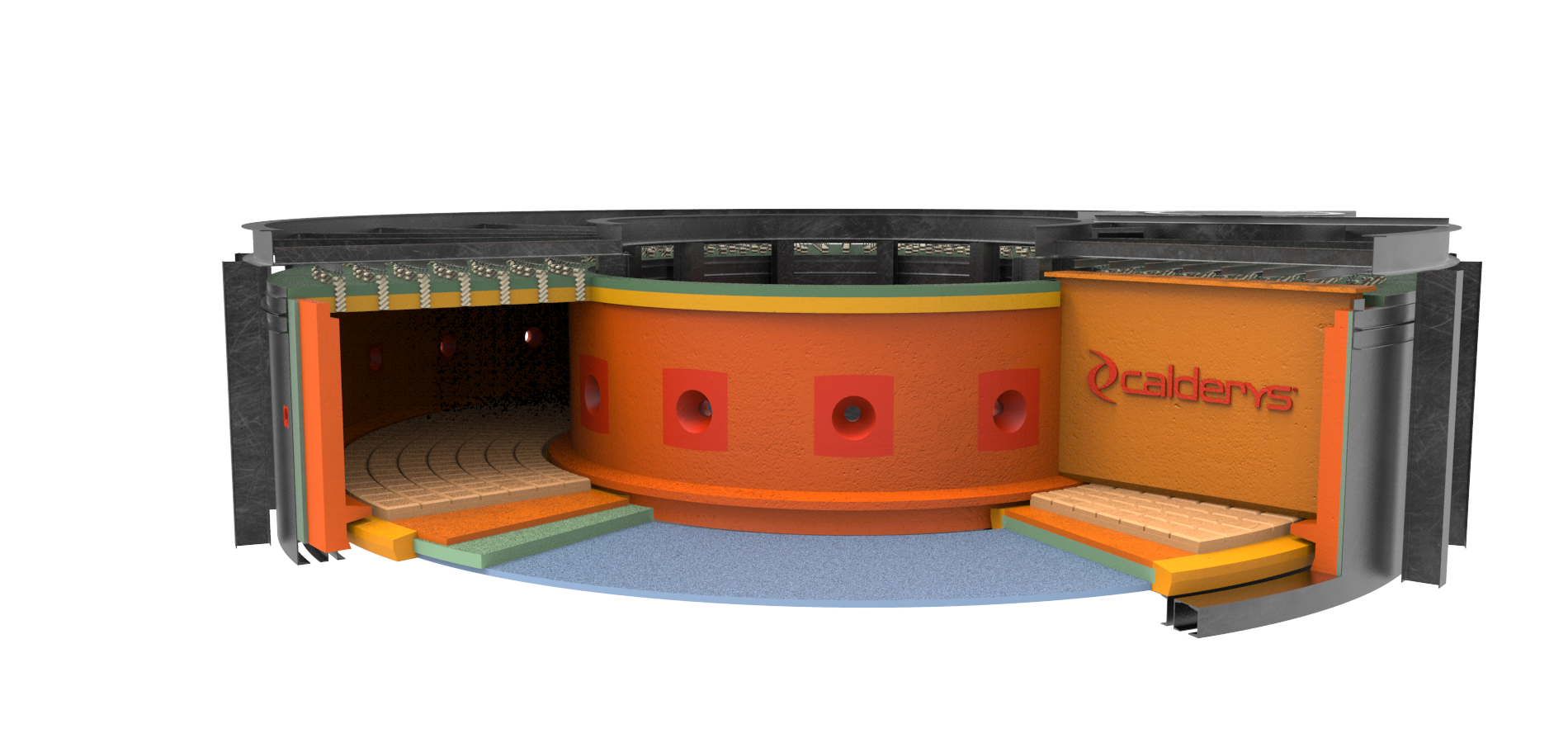

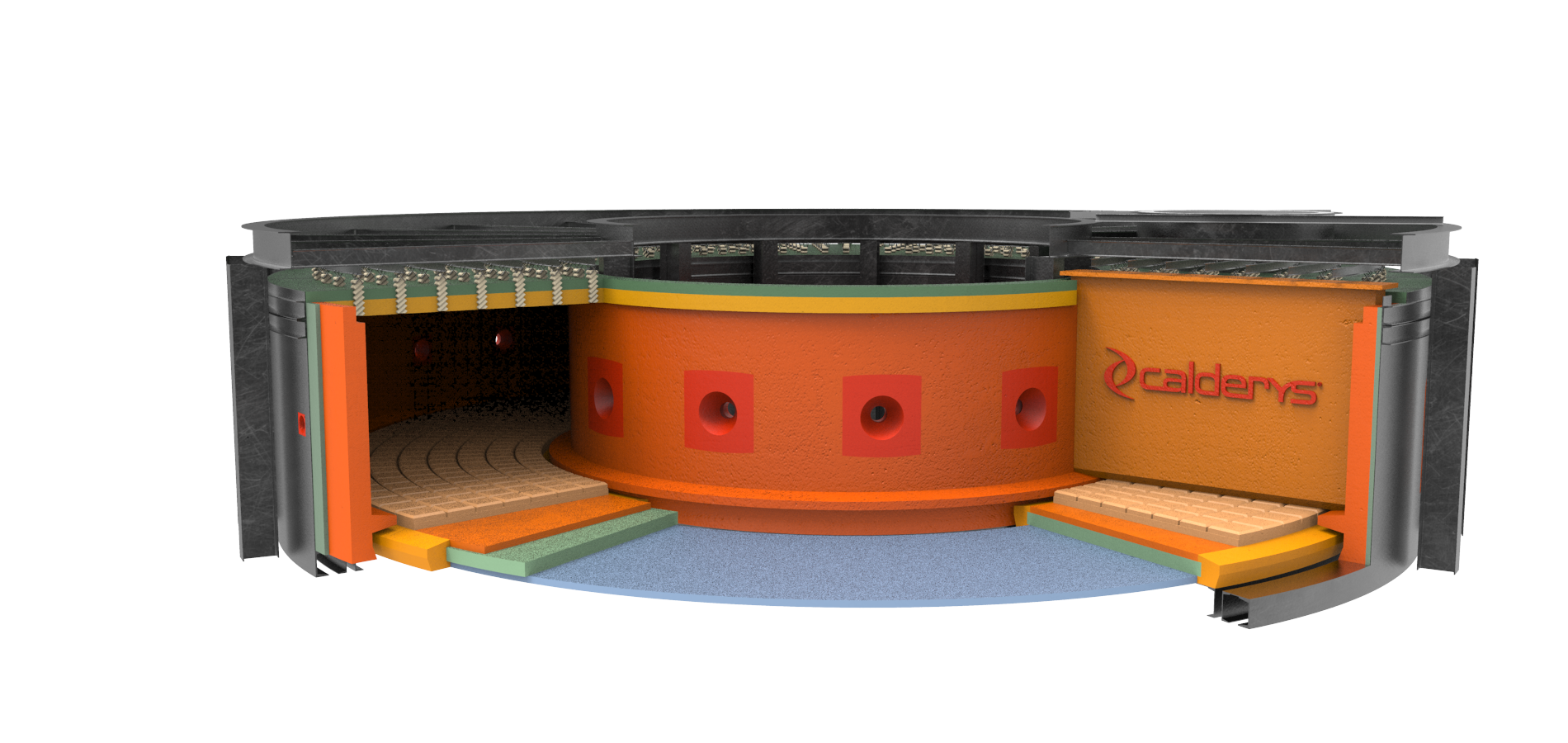

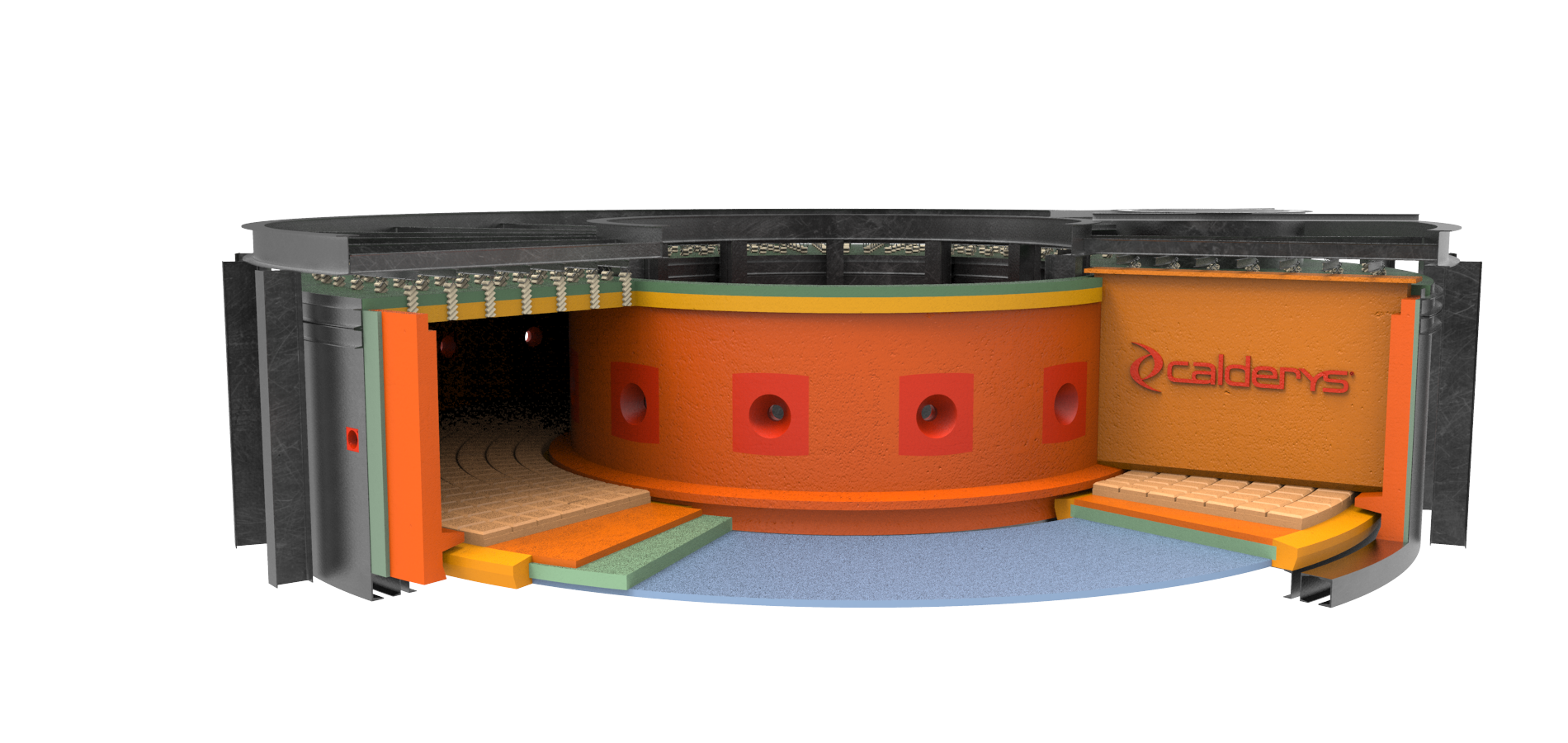

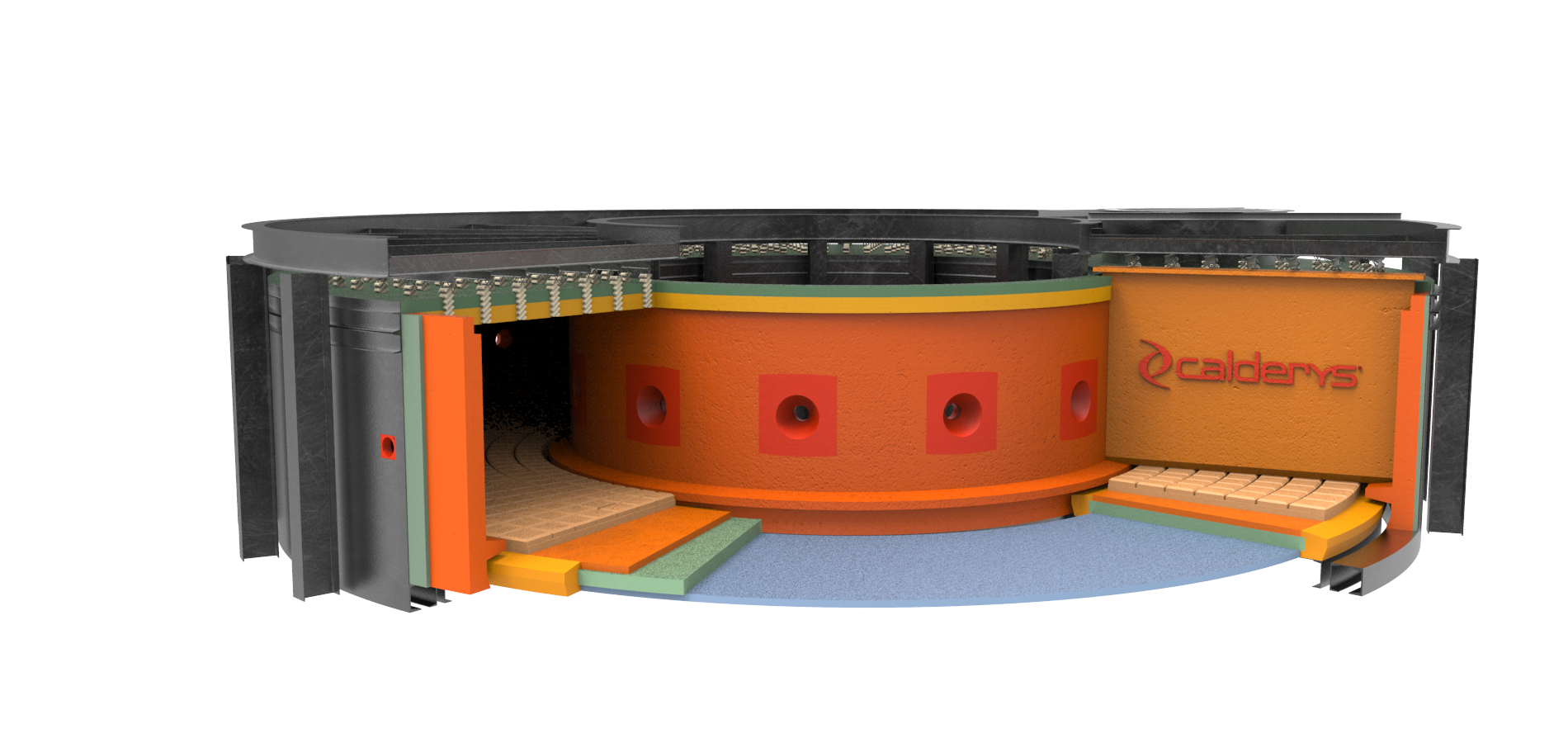

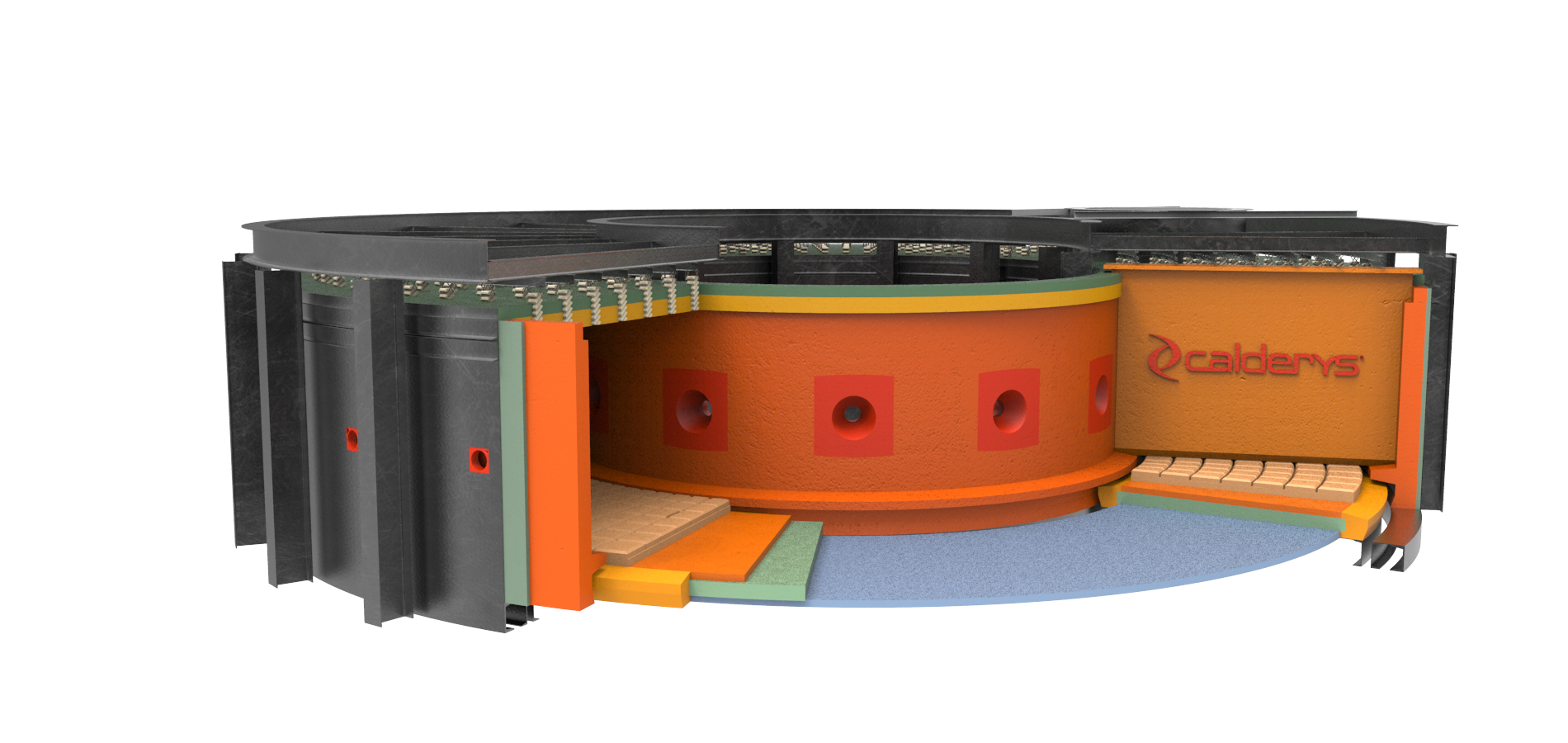

Rotary Furnace

These types of moving hearth furnaces tend to be used for variable size and geometry stocks. Our systems offer fast, user-friendly installation, good lining performance and overall energy cost savings. A very performing range of insulating products allows us to replace advantageously the ceramic fiber materials.

These types of moving hearth furnaces tend to be used for variable size and geometry stocks. The heat storage can sometimes be optimized by using grooves or humps. This can embrittle the structure of the hearth blocks. The unevenly distributed deposit of the stocks (slabs, billets or blooms) on the hearth can also contribute to inducing strong thermo-mechanical stresses in the blocks. Consequently, the materials have to reach good thermal shock resistance but also a good resistance to scale. Our systems offer fast, user-friendly installation, good lining performance and overall energy cost savings. A very performing range of insulating products allows us to replace advantageously the ceramic fiber materials.

We conduct an extensive audit of your process to design a customised solution from the insulating castables, precast shapes and large range of ceramic anchors in our monolithics portfolio.