Move towards Green Steel

The move towards Green Steel will significantly increase the roll-out speed of new generations of equipment such as Direct Reduced Iron (DRI) kilns and smelters.

To meet the targeted reduction of CO2 emissions, a large proportion of DRI kilns will be progressively fed with hydrogen along with the natural gas as per their availability. Hydrogen in the DRI process reacts with the refractory lining. Hence, the design and the refractory lining concept need to be adapted depending on the operating conditions, in particular the hydrogen content, in order to ensure long service life of the kiln.

OUR SERVICES

REFRACTORY SERVICES

Calderys offers a full range of services, tied in closely with our world-leading high temperature solutions product lines. We are continually upgrading our services and equipment to ensure that our products are easy and safe to use.

Material selection

Our expert engineers with a deep understanding of your local market, industrial process, and the chemical reactions in your equipment will work with you to identify the best products in terms of performance, lifetime, and cost.

PROJECT MANAGEMENT

Our end-to-end project management services offer you the peace-of-mind you need to focus on your production.

TECHNICAL SUPPORT

Calderys offers full technical support, thanks to a global network of technical experts, acting locally wherever you need it.

Your Equipments

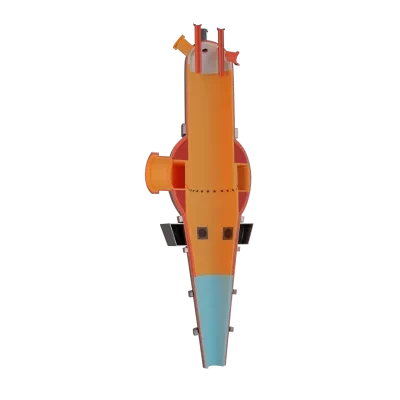

DRI

The Calderys’ unique approach is the zoning. A specific range of products has been designed to meet the process conditions of each zone within direct reduction technologies. Contact us to know more about our specific range of products per zone.

All Details