Leading steelmakers favor Calderys

Leading steelmakers favor Calderys refractories for their:

- Carefully chosen refractory products technologies, that are specifically designed and formulated to help enhance steel cleanliness.

- A complete understanding of the critical factors for steelmaking and refractory consumption; including installation, energy consumption, CO2 emissions, circular economy, and environmental footprint.

- High end maintenance products and services, specifically designed and optimized for maximum effectiveness.

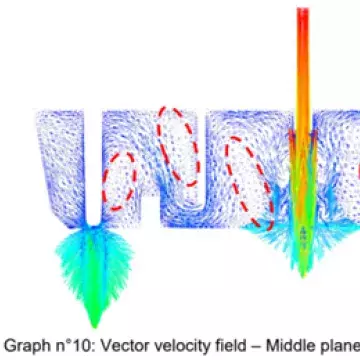

- Dedicated R&D program that strives for innovation, within the scope of product development, installation practices, equipment innovation.

OUR SERVICES

Gunning Maintenance

When it comes to gunning and repair, our approach is designed to strike a balance between equipment availability and refractory lifespan. We have developed specific machines for each type of equipment, with a gunning capacity of close to 200kg/min. All machines are available with electric batteries, for lower CO2 emissions.

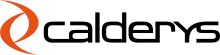

Fluid Flow & Numerical Simulations

We can conduct customised studies to optimise metal flow in the tundish based on multiple criteria including steel temperature, tundish dimensions and flow objectives.

Material selection

Our expert engineers with a deep understanding of your local market, industrial process, and the chemical reactions in your equipment will work with you to identify the best products in terms of performance, lifetime, and cost.

PROJECT MANAGEMENT

Our end-to-end project management services offer you the peace-of-mind you need to focus on your production.

TECHNICAL SUPPORT

Calderys offers full technical support, thanks to a global network of technical experts, acting locally wherever you need it.

Your Equipments

BOF Converter

The basic oxygen furnace (BOF) process is a method of primary steelmaking in which carbon-rich hot metal (produced by a blast furnace), is made into steel. It is one of the most common steel production process.

All Details

Electric Arc Furnace (EAF)

An electric arc furnace (EAF) is a furnace that heats the metal by means of an electric arc. Maximizing its availability is a key challenge for steelmakers.

All Details

Steel Ladle

The steel ladle is a bucket-shaped vessel used to transport and pour out molten steel. Calderys solutions are customized depending on the size of the ladle and the operating requirements.

All Details

RH Degasser

This vessel focuses on degassing the molten metal in order to produce ultra low carbon steel grades.

All Details

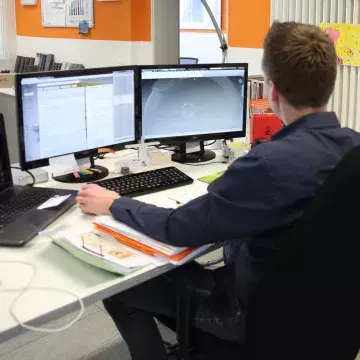

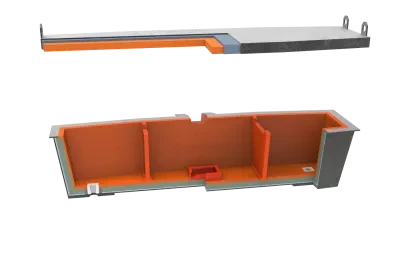

Tundish

The tundish is a critical reactor within the steelmaking process, where flow dynamics, refractory design and insulation requirements play a key role in ensuring and improving steel cleanliness.

All Details

CAS-OB

The CAS-OB (composition adjustment by sealed argon bubbling–oxygen blowing) is a ladle treatment process, used for the heating and alloying of steel.

All Details